About BreatheSafe

Protecting Operators, Protecting Workplaces

Our Vision

You give us a dust problem – we will find a solution

To lead the world in customised clean air solutions for challenging environments. BreatheSafe’s dust-smart and experienced team designs turn-key air pressurisation and purification systems to eliminate operator exposure to harmful dust and contaminants.

We believe that zero exposure is the only true path to zero harm, and we are committed to innovation, quality, and protecting people in the world’s toughest conditions.

Our Mission

Zero Harm through Zero Exposure

We create powerful solutions by manufacturing high-performance air filtration and cabin pressurisation systems tailored to real-world conditions. Our systems don’t just meet standards — they exceed them. We continuously improve by listening to customer feedback, investing in innovation, and ensuring a seamless, reliable experience for every client.

We proudly work alongside OEMs, mining operators, contractors, and industries where air quality is essential to safety and performance.

BreatheSafe Services

We believe lasting relationships start with respect — for our people, our customers, our partners, and the environment.

Research and Development

Innovating air quality solutions through advanced testing and continuous improvement.

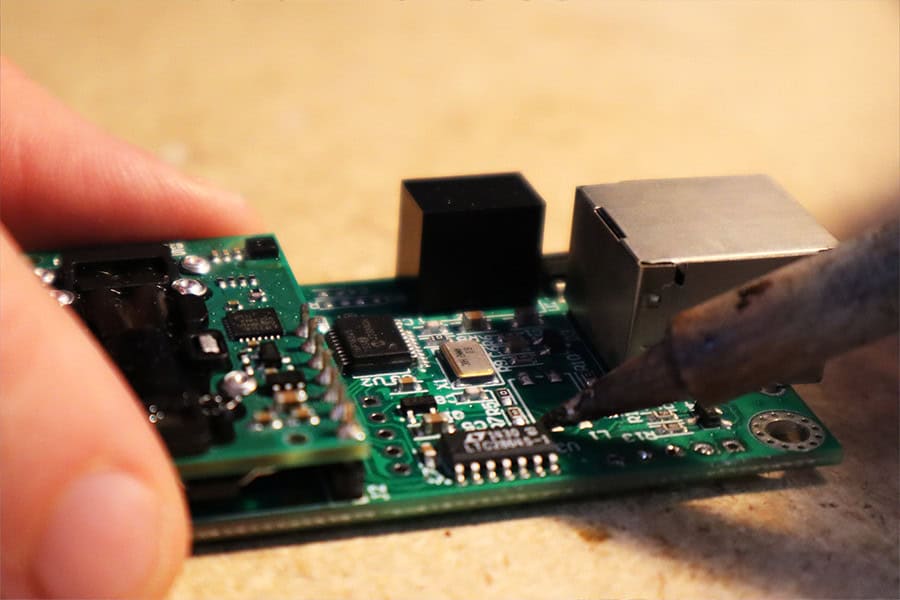

Electrical Engineering

Designing intelligent control systems for precision air quality management.

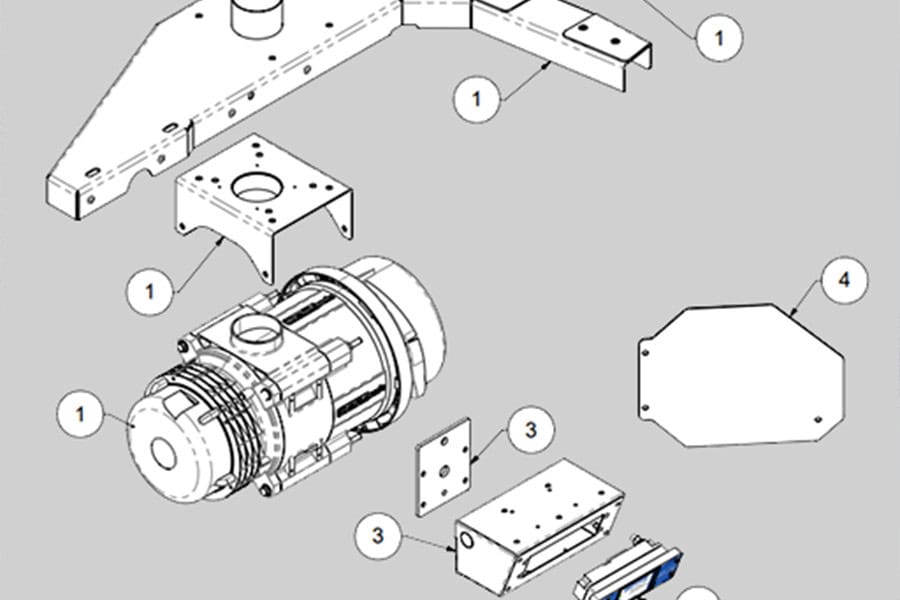

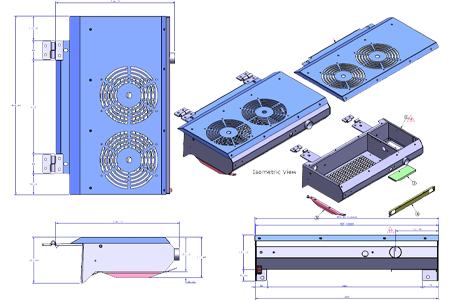

Mechanical Engineering

Engineering robust and reliable components to last lifetime.

Manufacture and Assembly

Building high-quality systems in-house with precision and attention to detail.

System Installation

On-site installation for full HVAC integration and optimal performance.

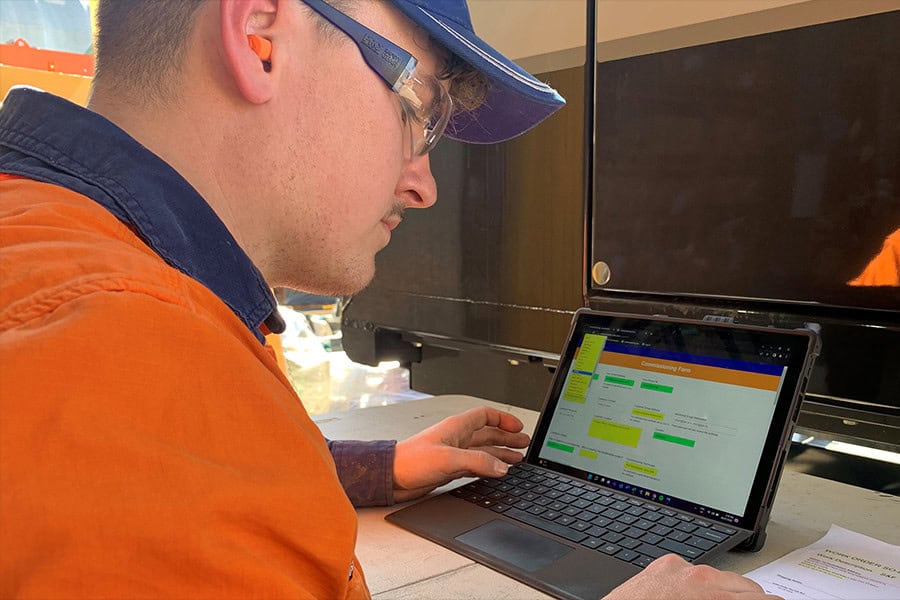

Commissioning and Auditing

Ensuring compliance, performance, and continuous system improvement through expert validation.

Key Milestones

Driven by Innovation, Built on Experience, Leading the Evolution of Air Filtration Systems

2021

OnGuard – Remote Air Quality Controller

In 2021, we developed a world-first: a patented cabin air monitoring and control system that real-time monitors cabin pressure, CO₂, and PM (Particulate Matter) in the breathing zone, with multiple sensor options available. We believe true zero exposure can only be achieved by measuring and reducing particulate matter inside the cabin.

2020

InPress – Touch Screen Cabin Pressure Monitor

In 2020, with the release of ISO 23875 and after nearly a decade of service, we upgraded our trusted INPRESS CPM. Drawing on customer feedback and operational insights, we developed the InPress, introducing new features such as CO₂ monitoring and the innovative event log, designed so operators can verify system performance during previous shifts.

2018

VacSafe – HEPA 24 Volt DC Vacuum Cleaner

In 2018, using data from our INPRESS CPM and NIOSH studies, we identified the need to better manage heavier contaminants brought into cabins by operators. Unable to find a rigid 24V DC HEPA vacuum, we developed and released the first of our VacSafe range — a 24V DC brushless HEPA-grade vacuum. We have since expanded the range to include 240V AC and 110V AC models.

2016 - 2017

TLi Powered HEPA Recirculated Pressuriser

To maintain clean air supply inside the cabin without compromising operator comfort, we developed volume control for our high-capacity units. Using our VSD brushless motor, we created the SBS controller to automatically regulate airflow.

2015 - 2017

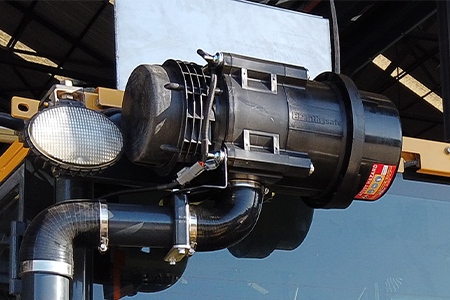

Development of our TL HEPA Air Pressuriser

After years of developing customised HVAC systems and cabin air pressurisers, both HEPA and non-HEPA, we took the leap to create our first custom-designed injection moulded air purifier. Drawing on our experience, we developed the TL unit, which still today offers the highest air volume and pressure generation in its size range anywhere in the world.

2014

Dual HEPA Filtration as standard where possible

After trials with an OEM customer in central Queensland, we identified the need for Dual HEPA filtration to achieve zero exposure, filtering both fresh and return air. In 2014, we began supplying HEPA upgrade kits for OEM HVAC units, a key step toward meeting ISO 23875 standards.

2012

CPM with Auto Cabin Pressure Control

In 2012, we developed our second world-first: a digital cabin pressure monitor with motor speed control to maintain pre-set cabin pressure. This breakthrough reduced system costs, extended filter life, lowered HVAC load, decreased cabin noise, and marked a major leap in pressurisation control and data recording.

2009 - 2011

Brushless VSD motor with Crossflow Blade

From 2009 to 2011, we expanded into heavy mining and developed a brushless motor to withstand high-hour operations. Along with our new crossflow motor and blade design, this innovation greatly improved system reliability and reduced lifetime costs.

2010

First Digital Cabin Pressure Monitor with Alarm

Recognising the critical importance of maintaining positive cabin pressure throughout a machine’s operation, we developed and released our own digital Cabin Pressure Monitor (CPM). At the time, the industry relied on analogue gauges that were prone to failure and offered no alarm system to warn of pressure loss.

2009

Mechanical Engineering in-house

In 2009, we made a significant investment in hardware, software, and training to bring our sheet metal design capabilities in-house. Today, our mechanical design department has grown to a dedicated team of five, reflecting our commitment to innovation, craftsmanship, and supporting our people.

1970

BreatheSafe always strived to develop the best

From custom air conditioning at Kev Dalton to heavy-duty systems at TRACS, and now at BreatheSafe, we’ve always focused on developing the best air conditioning and purification systems. Our Dual HEPA system now leads the way in cutting HVAC maintenance costs.

Our Air Filtration Systems

Comprehensive Systems for Cleaner, Safer Workspaces

Quality, Safety, and Sustainability

Proudly certified to ISO standards for quality, environment, and health and safety.

Join us and fuel your passion

Excited to make an impact? At BreatheSafe, we’re always looking for talented, driven individuals who share our passion for technology and innovation.