BreatheSafe at the Underground Operators Conference

BreatheSafe at the Underground Operators Conference

As the Underground Operators Conference approaches, we caught up with Kelvin Wright, BreatheSafe’s Western Region Sales Manger, to discuss why BreatheSafe is attending, the challenges facing underground mining, and how BreatheSafe is helping operators tackle air quality issues.

You can visit BreatheSafe at Stand 178 at the event.

Q1: Why is BreatheSafe attending the Underground Operators Conference?

Kelvin Wright: The Underground Operators Conference is one of the most targeted events for underground mining professionals. It brings together those directly involved in underground operations. We’re attending because it’s an excellent opportunity to engage with operators, OEMs, and contractors to understand their challenges and demonstrate how our technology can help them.

Q2: What makes underground mining so challenging when it comes to air quality?

Kelvin Wright: Underground mining environments are tough. Machines are constantly on the move, the conditions are harsh, and the equipment takes a real beating. The air quality can be significantly compromised due to the generation of hazardous dust particles like silica, silicate, and asbestos. Our goal is to showcase how our technology holds up in these environments and learn from attendees how we can continue to adapt to meet the industry’s needs.

Q3: Why is air quality in underground mining a pressing issue right now?

Kelvin Wright: Silica dust exposure is a major concern, especially with recent cases of silicosis coming to light. In March 2025, it was reported that 13 workers on Sydney tunnelling projects were diagnosed with silicosis. Just a year prior, in February 2024, two workers at Newmont’s Cadia gold mine were diagnosed with early-stage silicosis. These incidents have raised serious questions about current air quality regulations and whether they’re sufficient to protect workers.

The Australian Workers’ Union (AWU) has been calling for stricter silica exposure regulations since November 2024, and the NSW government recently formed a silica task force to enhance compliance monitoring. The pressure is on for the mining industry to address these risks head-on, and that’s where BreatheSafe comes in.

Q4: How does BreatheSafe technology help address these air quality challenges?

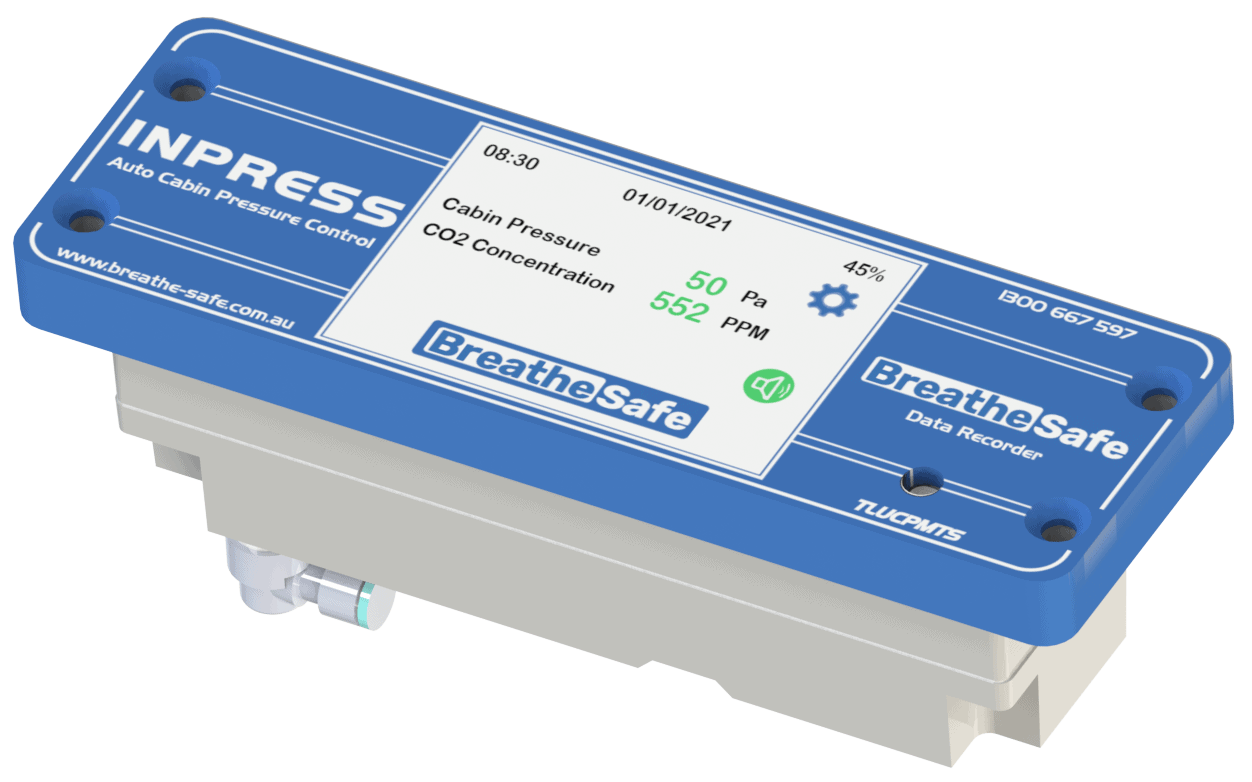

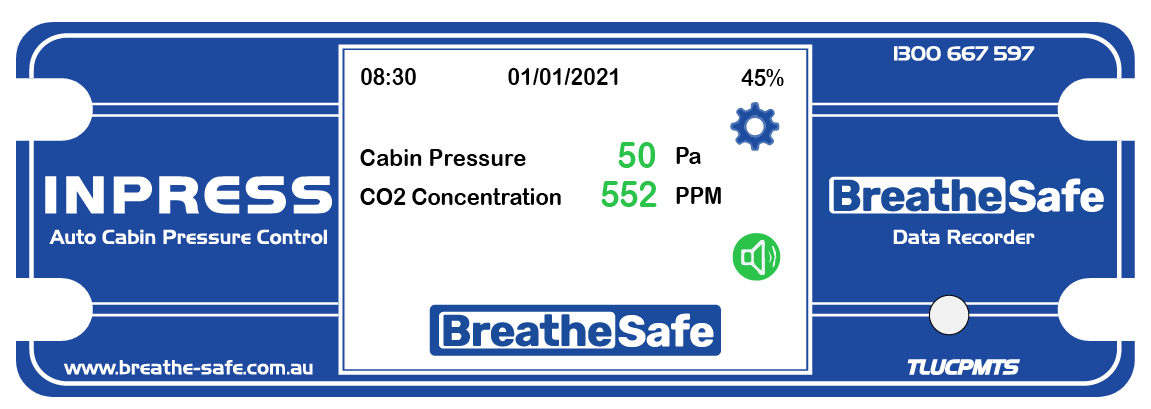

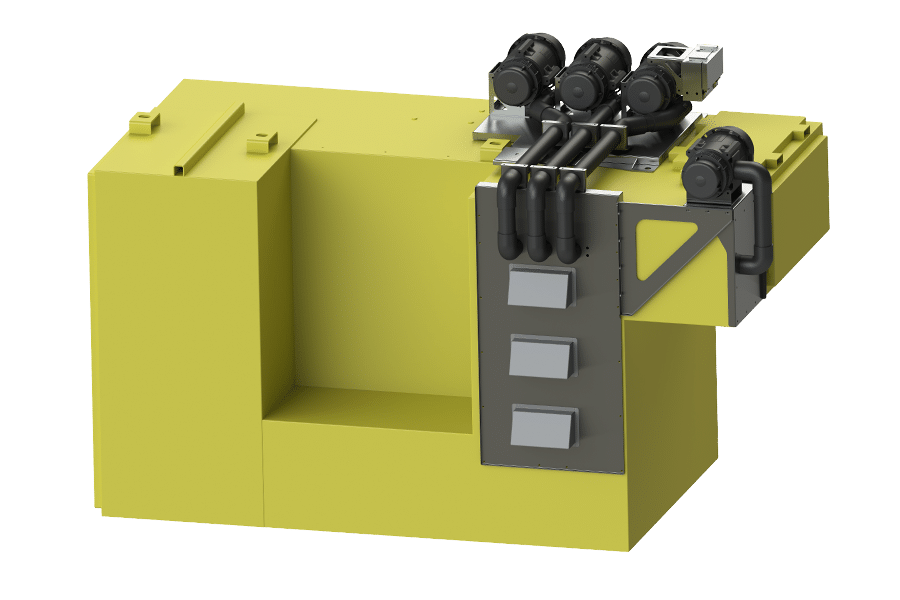

Kelvin Wright: The primary function of our systems is to create a clean, safe environment inside machinery cabins. We use High-Pressure HEPA Filtration Systems to prevent harmful airborne dust from entering, and we also scrub contaminants that do make their way inside whether from clothing, boots, or equipment. We also actively monitor CO₂ levels to ensure that operators aren’t exposed to hazardous concentrations.

Q5: How is BreatheSafe supporting compliance with new air quality regulations?

Kelvin Wright: Australia has adopted ISO 23875, which establishes strict requirements for air quality in operator enclosures. This standard requires controlling respirable dust, maintaining CO₂ levels, and conducting routine performance testing. Our systems are designed to not only meet but exceed these requirements, ensuring long-term safety and compliance.

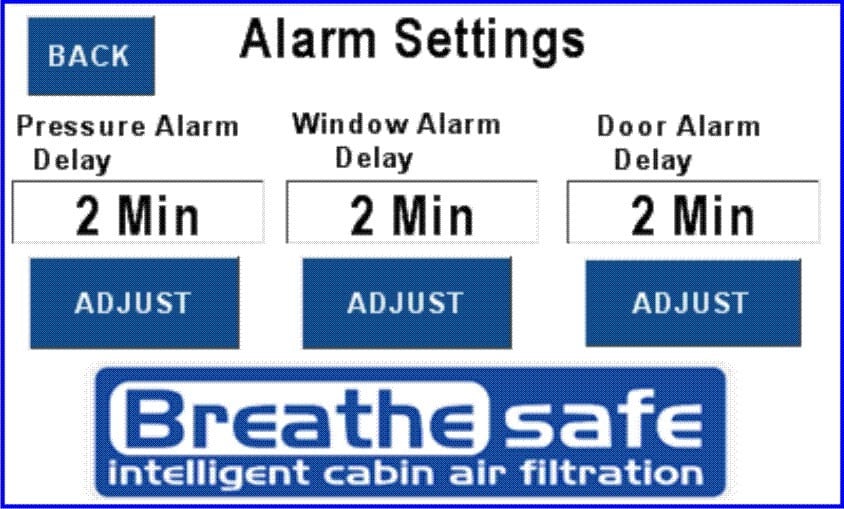

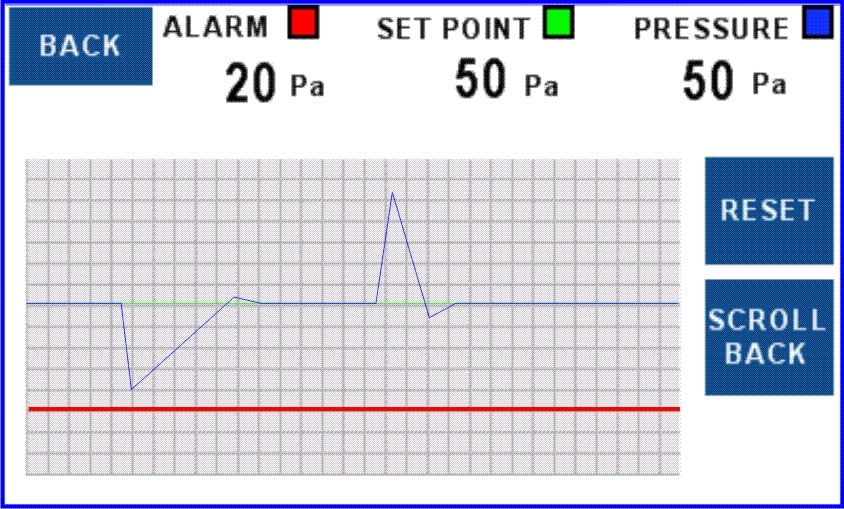

It’s important to understand that this is not a set-and-forget solution. Mining operators need to approach air quality as a continuous commitment. Our OnGuard technology helps maintain compliance by offering real-time visibility into air quality metrics, allowing operators to take proactive measures.

Q6: Some people think that underground ventilation systems alone can manage air quality. Is that true?

Kelvin Wright: Not at all. Ventilation systems move dust through tunnels but don’t ensure a clean environment inside operator cabins. Dust is constantly generated during mining operations, and ventilation alone can’t stop respirable particles from getting into cabs. Our focus is on protecting the specific environment where the operator works, inside the cabin, regardless of what’s happening around it.

Q7: Is BreatheSafe focusing on light vehicles in underground settings?

Kelvin Wright: Yes, definitely. Light vehicles such as Land Cruisers are widely used underground in large volumes. As mines move towards electrification to reduce diesel emissions, we see a huge opportunity to improve air quality in these vehicles as well. Our systems can be integrated into light vehicles to ensure they meet stringent air quality standards.

Q8: Why should people visit BreatheSafe at Stand 178 during the conference?

Kelvin Wright: We want to talk directly with underground mining professionals about how we can support them. Whether it’s about meeting compliance standards, protecting operators, or integrating our technology into light vehicles, we’re here to find solutions together. Plus, you can see our High-Pressure HEPA Filtration Systems in action and learn more about how we’re making underground operations safer.

If you’re attending the Underground Operators Conference, drop by Stand 178 to talk with us. Let’s discuss how BreatheSafe can help keep your workers safe and your operations compliant. In underground mining, safety starts with the air you breathe.