OnGuard™ Air Quality Manager

Connected Air Quality Management Across Your Fleet

Hover over the image to see 360 view

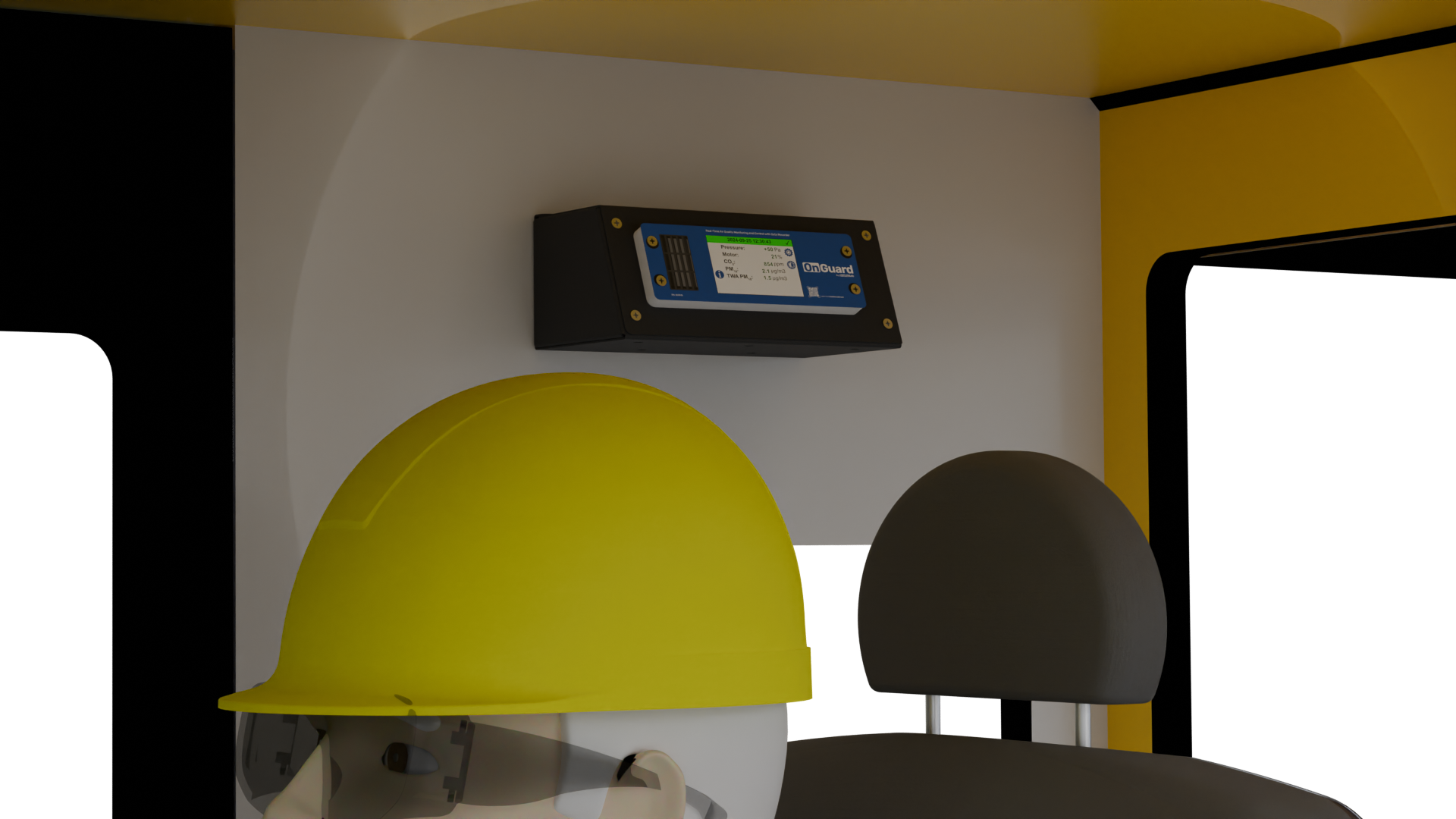

OnGuard™ Air Quality Manager

Connected Air Quality Management Across Your Fleet

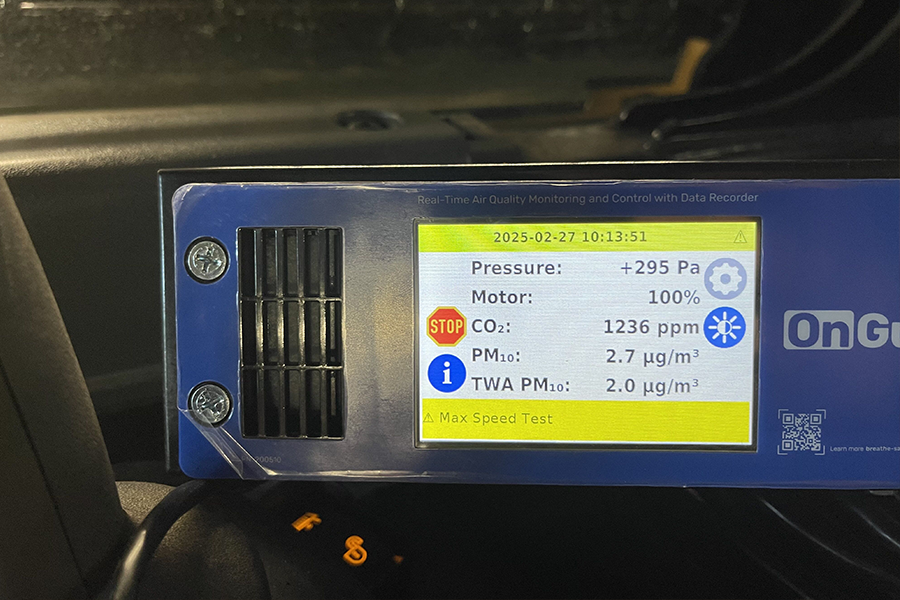

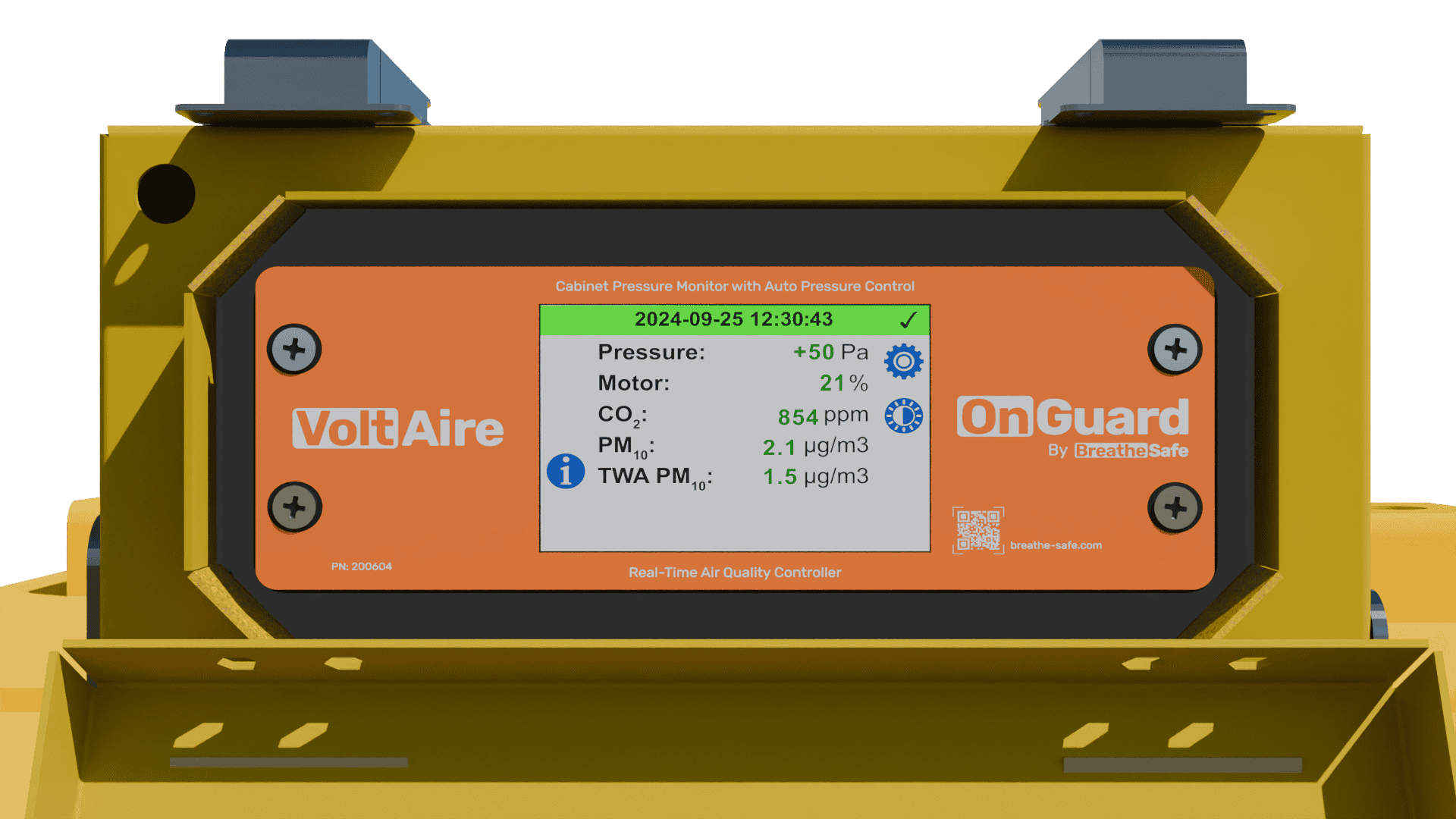

Designed to comply with and exceed ISO 23875 and MSHA regulations, delivers real-time measurement and data logging of cabin pressure (Pa), CO₂ levels, dust particulate count and mass, TWA, and other critical air quality metrics.

With over 6 years of data storage, plus standalone Wi-Fi and remote network access, live data and system configurations can be securely monitored anytime, anywhere.

Measures:

-

Pressure

Pressure

-

Motor Capactiy

Motor Capactiy

-

CO2

CO2

-

PM2.5

PM2.5

-

PM4

PM4

-

PM10

PM10

-

Temperature

Temperature

-

Humidity

Humidity

Applications

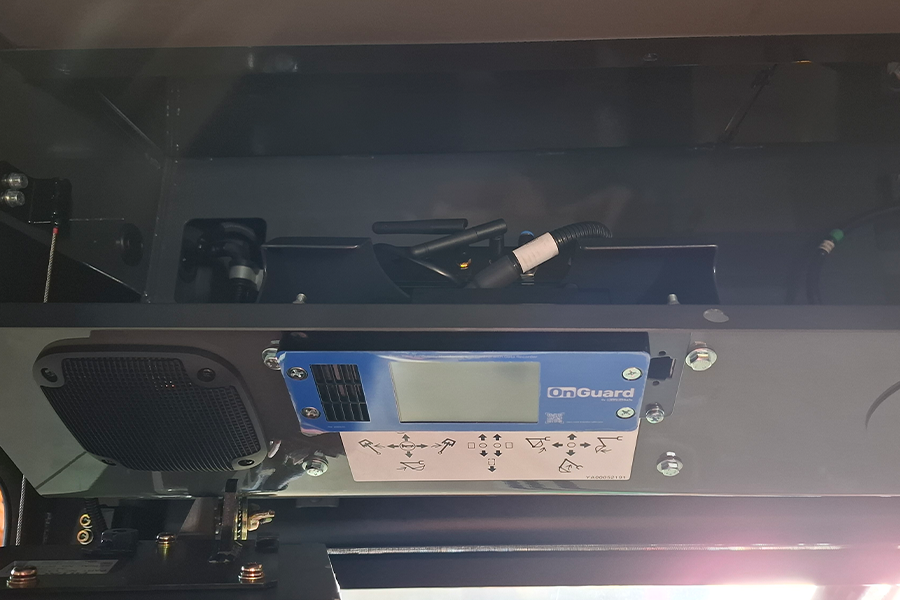

Operator Cabin Pressurisation

Electrical Enclosure Pressurisation

Clean Room Pressurisation

Features

Hover over the images to play the videos

Built-in CO₂ and PM Sensor

Continuously monitors air quality in the operator’s breathing zone, providing accurate real-time data while preserving cabin space.

Automatic Pressure Control

Automatically adjusts the pressuriser’s speed to maintain pressure, reduce filter loading and extend filter life.

Traffic Light System

Provides a clear visual indication of air quality status using a green–amber–red traffic light display for operator awareness.

Visual and Audible Alerts

Notifies operators immediately through sound and on-screen messages when air quality or pressure drops below safe levels.

High CO₂ Concentration Reaction

Automatically increases airflow in response to high CO₂ levels.

High Dust Concentration Reaction

Automatically increases airflow when high dust is detected to maintain cabin air quality.

Secure Data Storage

Store system data locally with the OnGuard network, supporting remote access and long-term record keeping.

Remote Data Management

Access real-time and historical data from anywhere using a web-based dashboard for monitoring, configuration, and reporting.

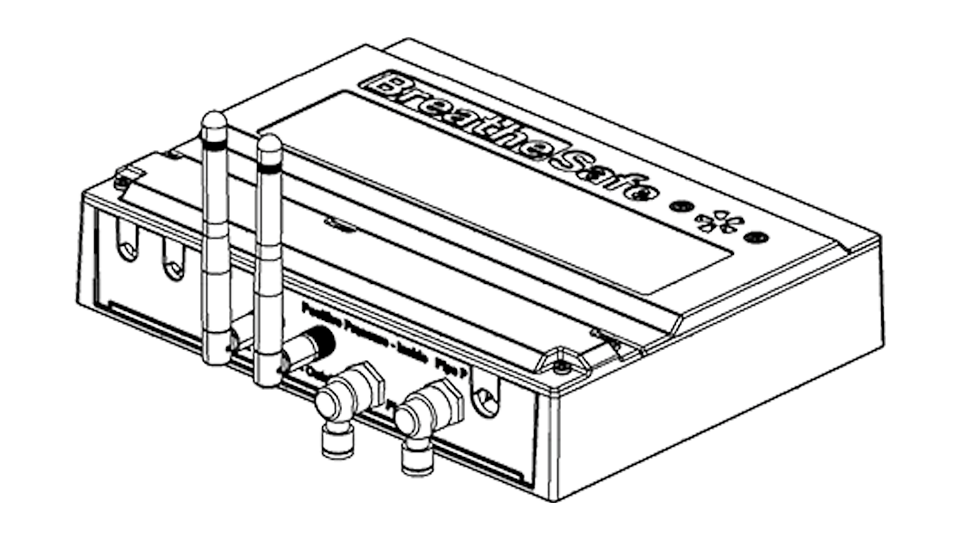

Specification

| Parameter | Value |

|---|---|

| Length | 206.9 mm |

| Height | 105 mm |

| Width | 197.3 mm |

| Weight | 609.25 g |

| Voltage | 12 - 24 V |

| Current | 1 (typical) - 4.8 A (absolute maximum) |

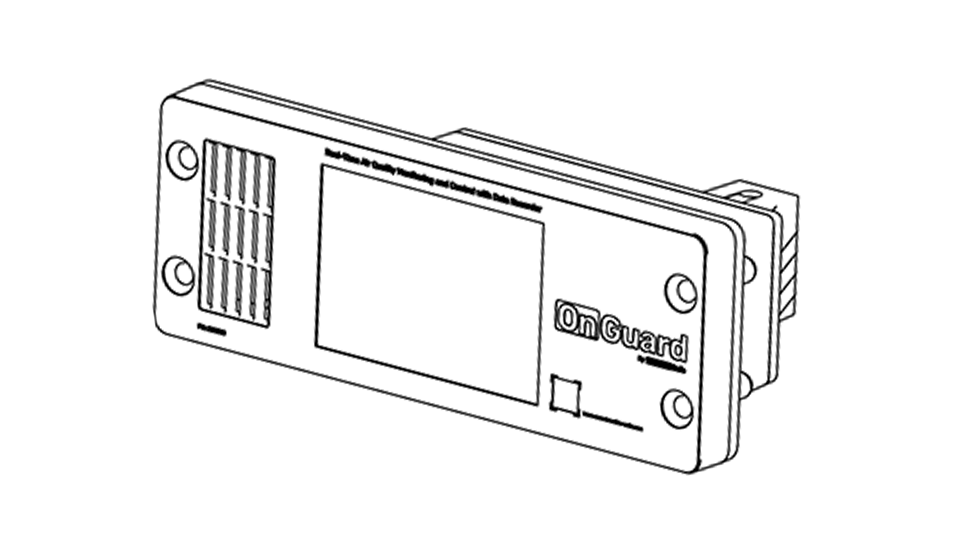

| Parameter | Value |

|---|---|

| Length | 68.8 mm |

| Height | 54.9 mm |

| Width | 186 mm |

| Weight | 294 g |

| Voltage | 12 VDC (Powered via RJ45 from Main Unit) |

| Current | < 85 mA |

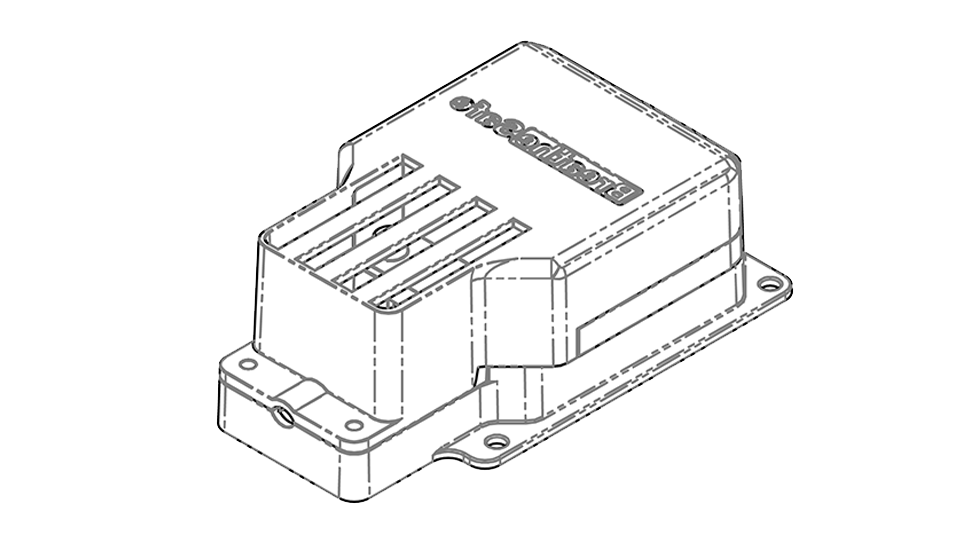

| Parameter | Value |

|---|---|

| Length | 120 mm |

| Height | 42 mm |

| Width | 66 mm |

| Weight | 140 g |

| Voltage | 12 -24 VDC |

| Current | < 50 mA |

Video Support

OnGuard Demonstration

OnGuard Air Quality Manager

OnGuard Operator Instructions

Other Controllers

InPress Controller

CabAire Controller

View All Controllers