Advanced Protection for Operator Cabins

Protect operators with a dual HEPA filtration system in a pressurised cabin.

Hover over the image to see 360 view

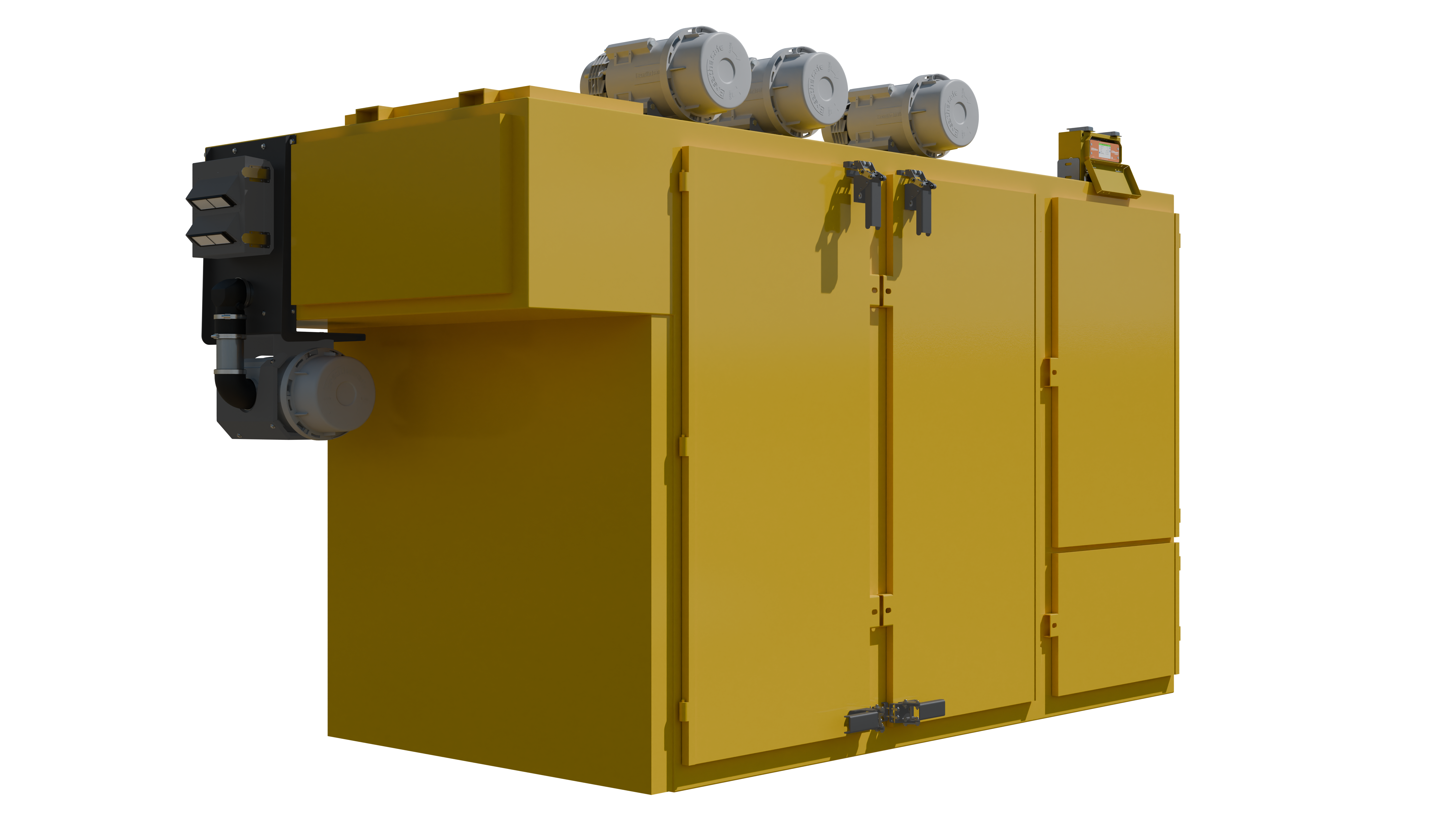

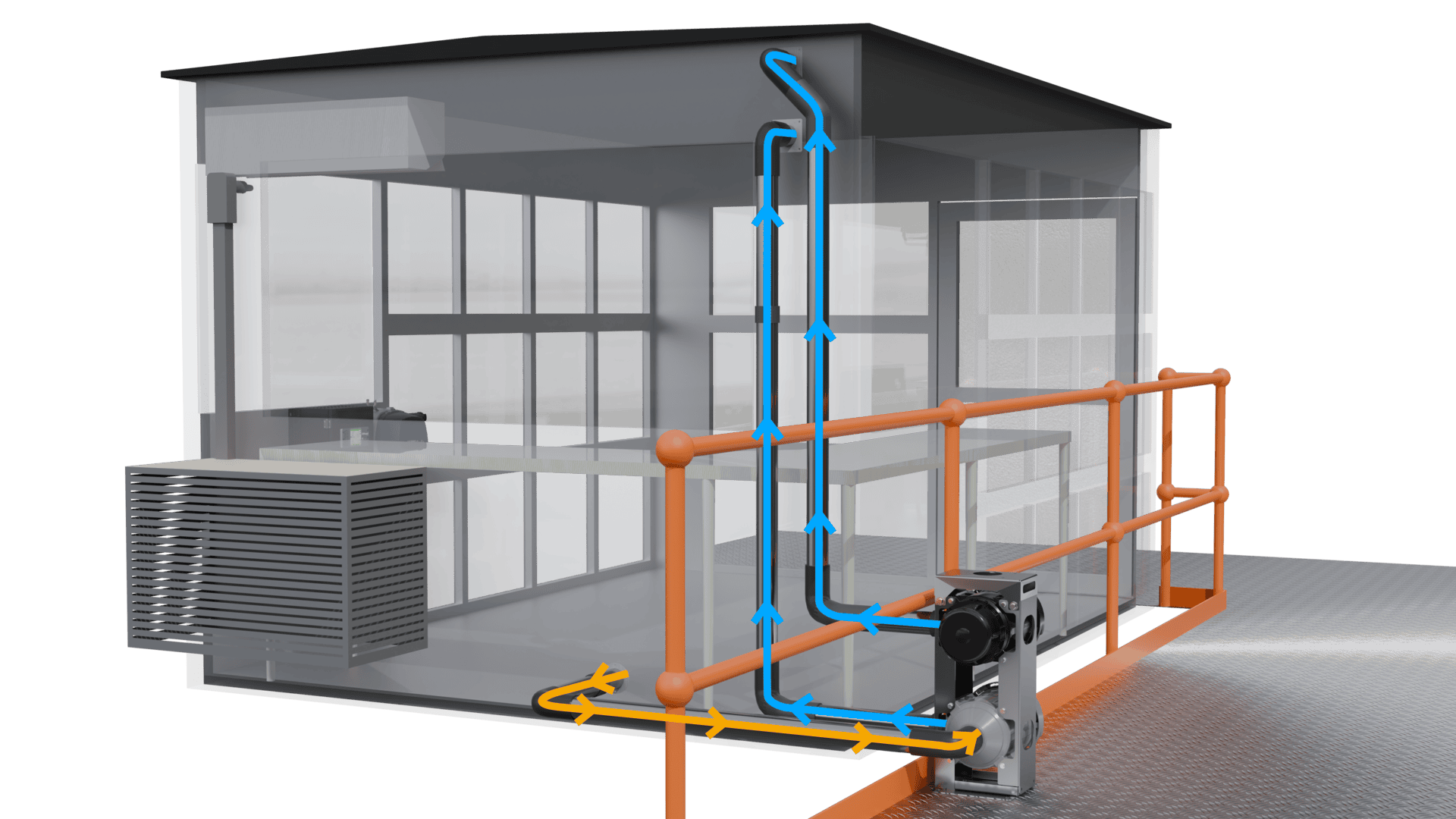

Closed-Circuit Filtration Systems

Dual HEPA-Filtered, Pressurised, Monitored and Controlled

Intelligent Air Filtration Technology

BreatheSafe system intelligently regulates and maintains positive cabin pressure at a preset level, preventing dust ingress.

Closed-Circuit Filtration System

BreatheSafe closed-circuit system ensures every air entry point is HEPA-filtered, eliminating unfiltered airflow and maximizing protection.

Complete System Solutions

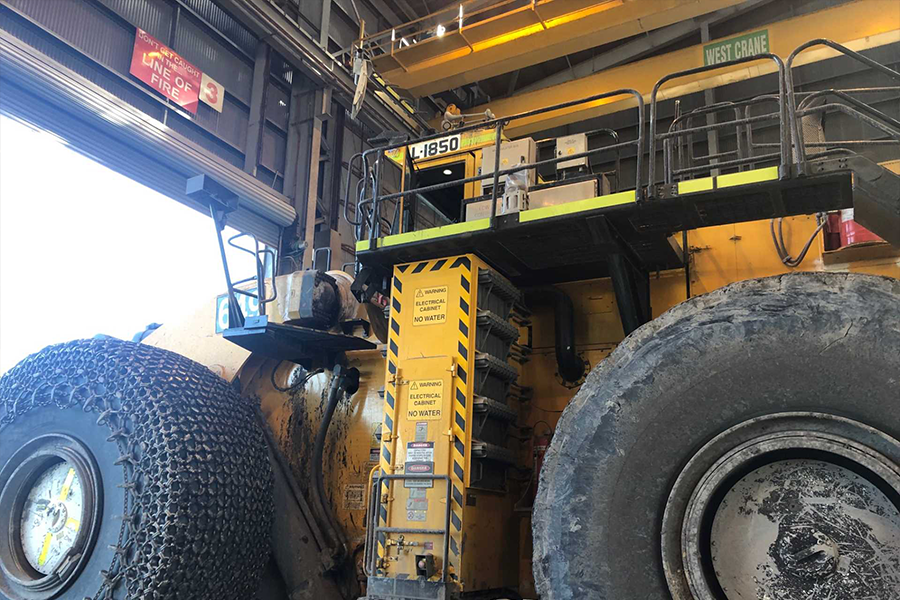

Fully integrated air filtration and pressurisation systems, custom-designed to fit a wide range of machines.

Applications

Support a wide range of industries, including Mining, Civil Construction, Tunneling, Landfill, Agriculture, Smelters etc.

BreatheSafe Components

TL High-Pressure HEPA Pressuriser

Equipped with a HEPA H14 filter, variable speed motor, and fully IP66-rated design, it delivers high-performance cabin pressurisation and reliable protection in harsh environments.

Air Quality Monitor and Controller

Exceeds industry standards such as ISO 23875 and the MSHA Silica Rule through real-time monitoring, precise control, and seamless integration with BreatheSafe’s HEPA filtration systems.

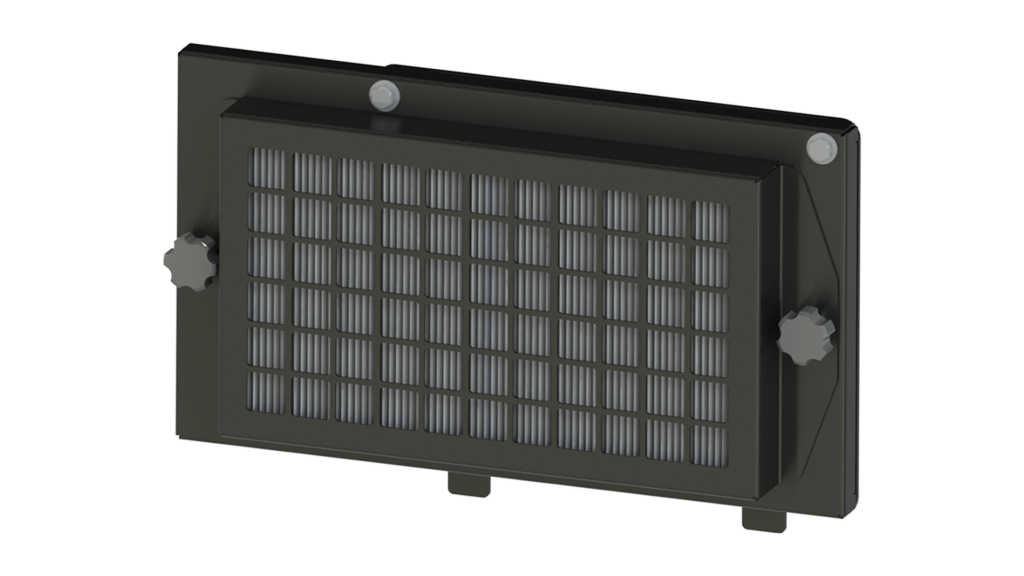

Custom Panel HEPA Recirculation Filter

Designed to integrate with the cabin’s HVAC system, captures 99.95% of particles ≥0.3 microns, providing clean air, extended filter life, and easy installation in a durable, OEM-ready metal housing.

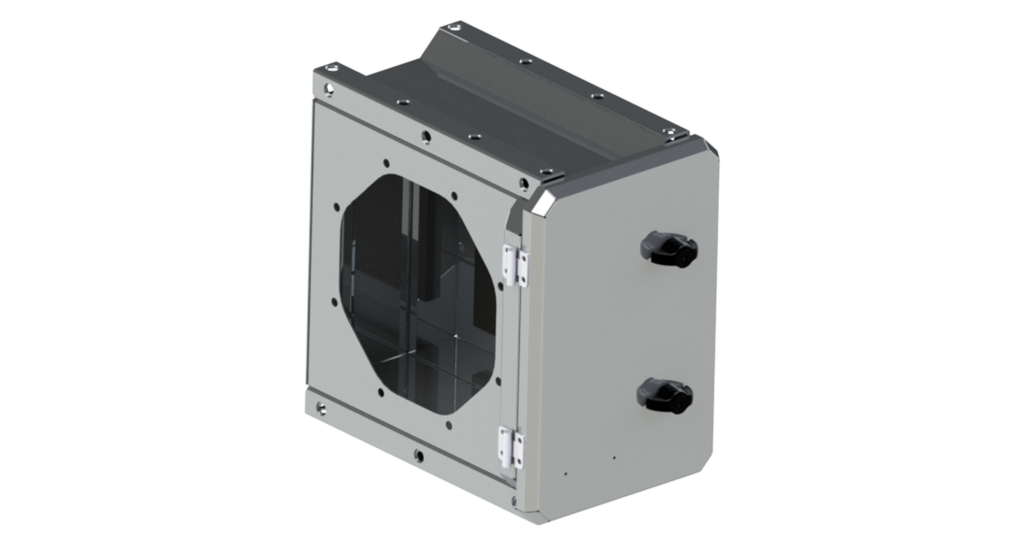

Powered HEPA Recirculation Filter

Equipped with a HEPA H14 filter, variable speed motor, actively filter recirculated air, rapidly reducing particle levels after door openings and ensuring the cleanest air in the operator’s breathing zone.

Custom Install Kit

Designed for flexibility and precision, includes all components needed for seamless OEM integration and durable, efficient installation across a wide range of machine types.

Activated Carbon Filter

Remove harmful gases, vapours, and odours, adsorbing airborne chemicals that standard filters can’t capture. Ideal for environments with diesel exhaust, VOCs, and chemical exposure.

How It Works

Pressurise The Cabin With Clean Air (1st HEPA)

The BreatheSafe system protects operators by pressurising cabins with HEPA-filtered air, preventing hazardous dust, silica, and airborne contaminants from entering.

Our HEPA air filtration system helps you exceed industry standards, such as MSHA, ISO 23875 or RS20. Ensuring a safer work environment in mining, construction, and heavy industries while reducing respiratory risks.

Recirculating and Filtering In-Cabin Air (2nd HEPA)

Even in a sealed cabin, contaminants can be introduced through clothing and equipment. BreatheSafe continuously recirculates in-cabin air, filtering it twice through HEPA-grade filtration to remove fine dust, allergens, and pathogens.

The second stage of filtration maximises efficiency to shorten decay time, rapidly reducing airborne contaminants and restoring clean air within minutes. It means that operators breathe cleaner air faster, minimising exposure to harmful particles while enhancing HVAC efficiency and overall cabin air quality.

Air Quality Controller Monitors The Air

BreatheSafe controllers monitor air quality in real time, eliminating manual inspections and reducing dust exposure. By analysing particulates, pressure, and temperature, they optimise system performance and extend component life.

The OnGuard controller features an automated high-dust and CO₂ flush, purging contaminants when needed. This maintains optimal air quality, prevents CO₂ buildup, and reduces operator fatigue, ensuring a safer, more productive work environment.

Filtering VOCs Using Activated Carbon Add On

Industries such as mining, agriculture, landfills, smelters, and industrial processing expose operators to volatile organic compounds (VOCs), exhaust fumes, and chemical vapours, increasing health risks.

The BreatheSafe activated carbon module effectively absorbs harmful gases, preventing toxic airborne chemicals from accumulating inside the cabin.

Powered Recirculation Filter Add-On (3rd HEPA)

In extreme environments where airborne dust levels remain consistently high, continuous removal of particulates is essential for maintaining safe cabin conditions.

The BreatheSafe Powered Recirculation Filter unit draws in dusty cabin air, filters it through a HEPA H14 filter, and recirculates clean air back.

Reducing cabin decay time and minimising dust loading on the HVAC recirculation filter.

Media

BreatheSafe System Explanation

Exceed ISO 23875 with BreatheSafe

The Best Air Filtration System Setup

OnGuard Remote Controller

InPress Controller + CO₂ Sensor

Filter Replacement Guideline

Other Solutions

Electrical Cabinet Pressurisation

Clean Room Pressurisation

Build Your Own