Keeping Underground Crews Safe with OnGuard!

In underground activities, especially tunnelling and mining, dust exposure and poor air quality are critical health hazards. Limited ventilation, restricted air circulation, and the accumulation of carbon dioxide can quickly create unsafe working conditions for machine operators and crew members. To address these challenges, BreatheSafe designs and installs advanced filtration and pressurisation systems that provide operators with a clean, safe, and comfortable environment even in the harshest underground settings.

The Challenge of Underground Air Quality

Unlike open-air environments, underground worksites have very limited natural ventilation. Dust generated from drilling, cutting, and vehicle movement can remain suspended in the air for long periods.

At the same time, carbon dioxide produced by diesel engines, blasting activities, or human respiration can accumulate within enclosed spaces.

These conditions can cause a drop in oxygen concentration, increase operator fatigue, reduce visibility, and pose long-term respiratory risks. Maintaining air quality in such an environment requires a continuous and intelligent approach.

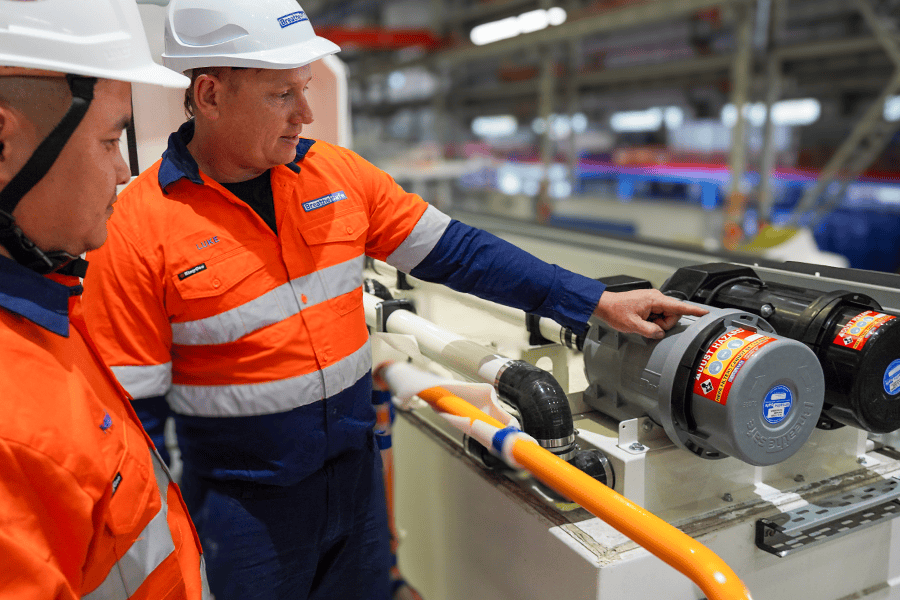

Photo of BreatheSafe and Stairway inspecting the installation of an OnGuard system on a Tunnel Boring Machine.

How OnGuard Keeps Operators Protected

To ensure the safety of operators, BreatheSafe’s OnGuard air quality manager continuously monitors and manages air quality inside control rooms, break rooms, medical rooms, and offices.

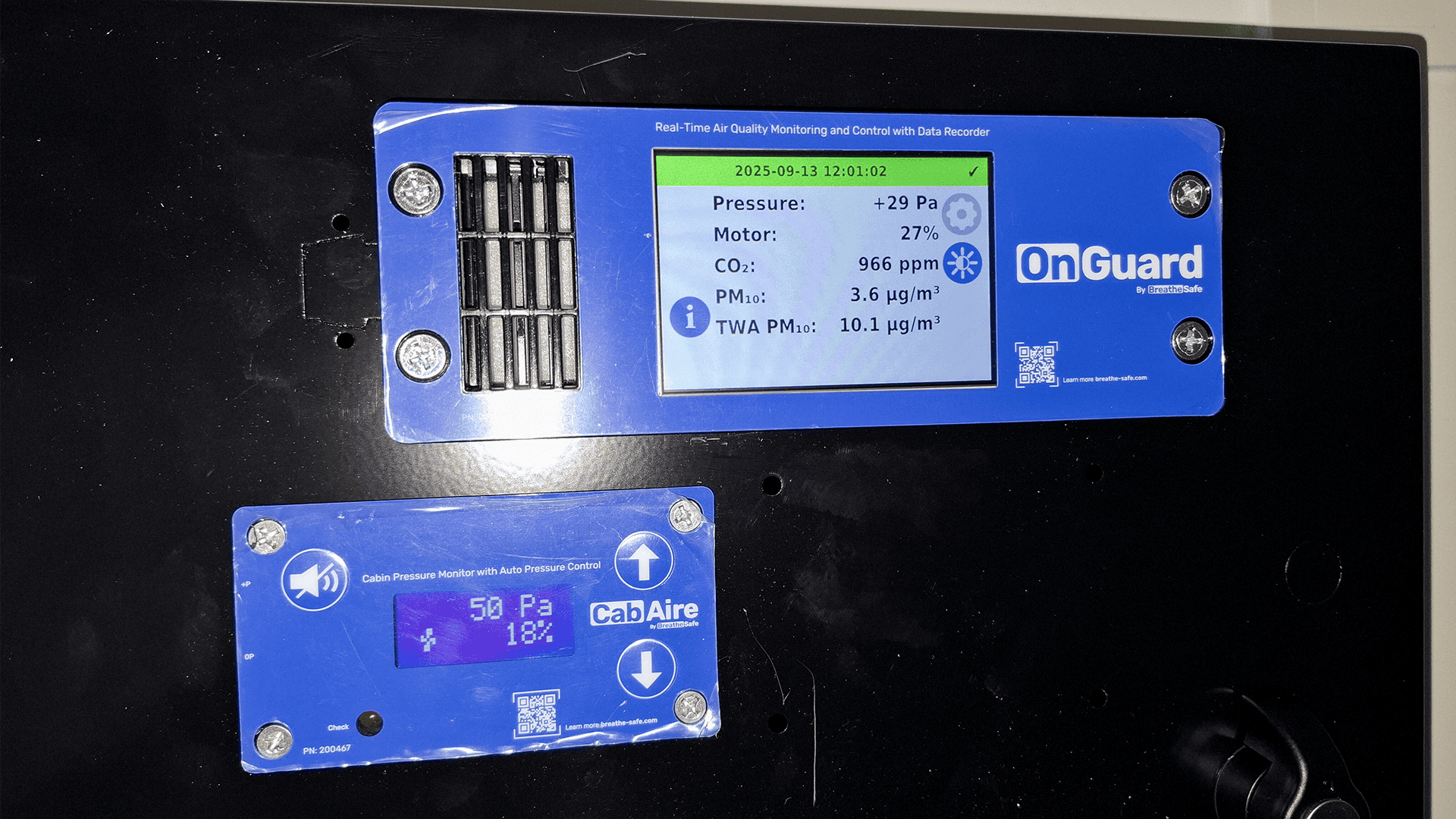

The system automatically detects changes in pressure, carbon dioxide (CO₂), and dust levels, then reacts intelligently to any changes in air quality. It maintains positive pressure inside the room to prevent contaminated air from entering and logs air quality data for compliance and performance tracking.

This fully automated process allows operators to focus on their tasks while OnGuard maintains a stable and safe working environment without the need for manual adjustment.

Photo of one of the OnGuard systems on a Tunnel Boring Machine.

Custom Solutions for Demanding Conditions

Not only the RoomSafe system, but BreatheSafe also provides tailored solutions for underground machines, as well as electrical enclosures. Each system is custom-designed to meet specific site conditions or equipment requirements, ensuring optimal performance, safety, and reliability.

Whether it is protecting operators underground, safeguarding electrical components from dust and heat, or maintaining clean air in break rooms, BreatheSafe delivers integrated air quality solutions that enhance both safety and operational efficiency across all environments.

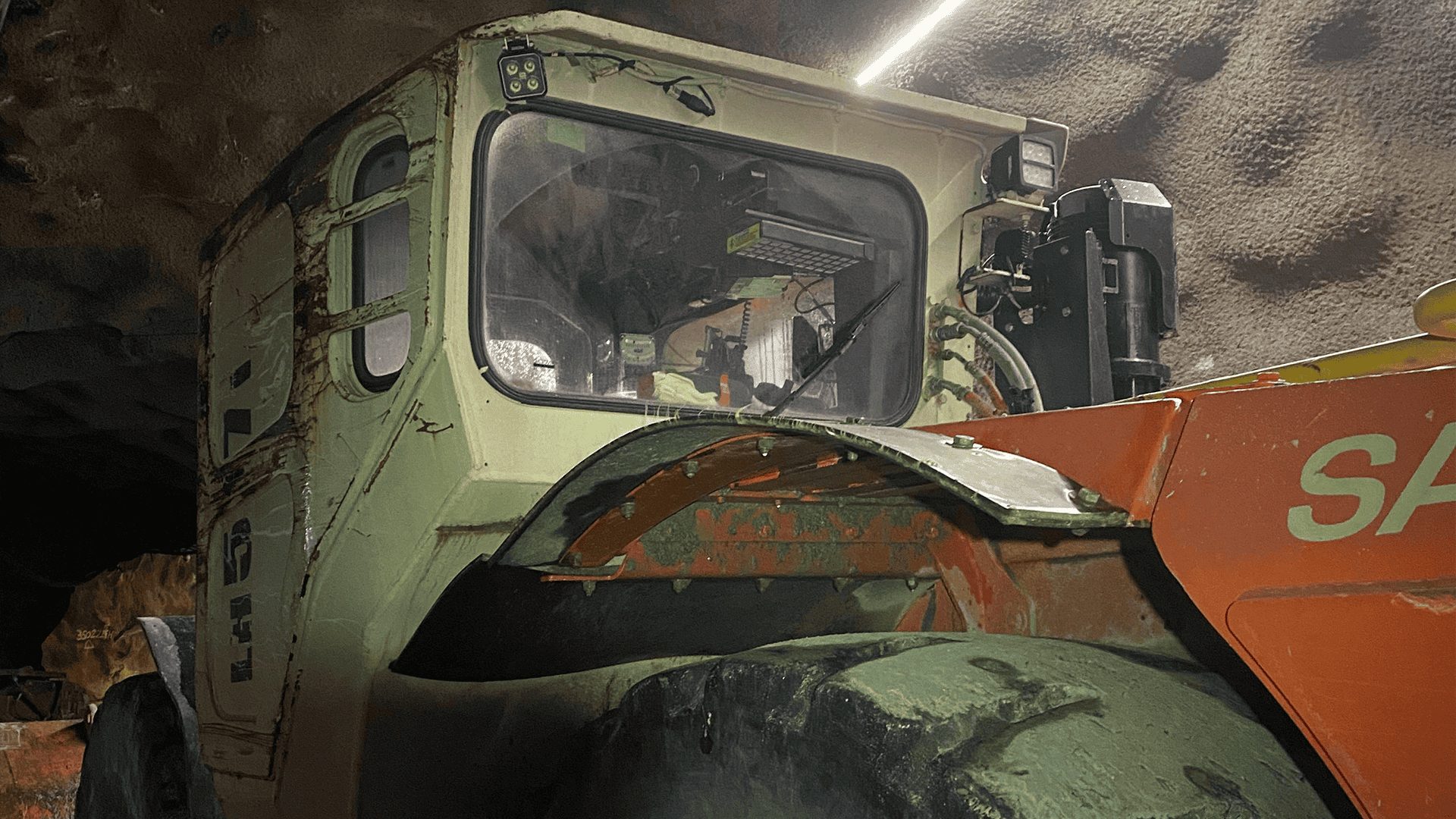

Operator Cabins – BreatheSafe System

What it does:

BreatheSafe system filters and pressurises air in mobile machinery like excavators, dozers, trucks, and drills.

Key features:

-

HEPA H14 filtration removes 99.995% of harmful dust (carbon filter optional for gas removal)

- HEPA Panel Return Air Filter scrubs and filters the internal air

-

Positive pressure keeps contaminants out

-

Real-time monitoring of CO₂, PM2.5, airflow, and cabin pressure

Why it matters:

It protects machine operators at the source of exposure and helps your site meet safety standards for air quality.

BreatheSafe system fitted to a Sandvik Loader 517i

Electrical Enclosures – VoltAire System

What it does:

VoltAire protects sensitive electronics inside the enclosure by preventing dust ingress and heat build-up. This improves the reliability and longevity of critical electrical components.

Key features:

-

EPA E11 pressurisers filter incoming air.

-

Positive pressure prevents contaminated air from entering.

-

Automatically manages pressure and flushes out hot air when electronics begin to overheat.

Why it matters:

Electrical components are highly sensitive to heat and airborne contaminants. Reducing maintenance costs and extending equipment lifespan.

VoltAire system fitted to a Caterpillar 796AC HV Cabinet

Our Commitment to Zero Exposure

At BreatheSafe, our mission is clear: Eliminate operator exposure to airborne contaminants. With the integration of OnGuard, we are helping create safer underground environments where operators can work confidently and efficiently, knowing their health and well-being are protected.