Mine Safety and Health Administration

MSHA Silica Final Rule

Lowering Miners’ Exposure to Respirable Crystalline Silica and Improving Respiratory Protection

Scope: Mining Operations in the United States

What is the MSHA Silica Rule and Why Does It Matter?

The MSHA Silica Final Rule is a critical regulation aimed at reducing miners’ exposure to respirable crystalline silica, a hazardous substance linked to serious health conditions such as silicosis, lung cancer, and other respiratory diseases. This rule establishes clear requirements for monitoring, controlling, and limiting silica exposure in mining environments. By enforcing stringent permissible exposure limits (PEL) and requiring effective engineering controls, the rule seeks to protect worker health, improve safety, and ensure compliance with modern occupational standards. It emphasizes the mining industry’s responsibility to create healthier work environments and reduce long-term health risks for miners.

Who Does the MSHA Silica Rule Apply To?

The rule applies to all mining operations in the United States, including surface and underground mines, where workers are at risk of exposure to respirable crystalline silica. Key stakeholders include mine operators, safety managers, and equipment manufacturers responsible for implementing engineering controls, such as improved ventilation systems or wet drilling techniques. Additionally, miners and regulatory bodies are directly impacted, as the rule ensures workers are equipped with proper training, medical surveillance, and protective measures to mitigate silica-related health risks. Compliance is essential for maintaining workplace safety, adhering to regulatory obligations, and fostering a culture of health and safety in mining operations.

MSHA Silica Rule Requirements

- Exposure Thresholds:

-

- Permissible Exposure Limit: Miners’ exposure to respirable crystalline silica must not exceed 50 micrograms per cubic meter of air (µg/m³), averaged over an 8-hour time-weighted average (TWA).

- Action Level: If exposure levels reach or exceed 25 µg/m³, averaged over an 8-hour TWA, mine operators are required to implement additional protective measures, including exposure monitoring and medical surveillance.

-

- Exposure Monitoring:

-

- Regular sampling will assess miners’ exposure to respirable crystalline silica.

- Use sampling devices that meet the characteristics of respirable-particle-size-selective samplers as specified in ISO 7708:1995.

-

- Reporting and Recordkeeping:

-

- Promptly notify miners of their exposure levels following sampling.

- Maintain accurate records of all exposure measurements and corrective actions taken. Accredited

laboratories are held to internationally recognized laboratory standards and must participate in

quarterly proficiency testing for all analyses within the scope of the accreditation.

-

- Implementation:

-

- Under the final rule, the mine operator must install, use, and maintain engineering controls, supplemented by administrative controls, when necessary, to keep each miner’s exposure at or below the PEL.

- Examples include:

- Wet drilling techniques to suppress dust generation.

- Enhanced ventilation systems to dilute and remove airborne contaminants.

-

- Respiratory Protection:

-

- When engineering controls cannot maintain exposures at or below the PEL, provide miners with appropriate respiratory protection in accordance with ASTM F3387-19 standards.

-

- Training Programs:

-

- Develop and implement training programs to educate miners on:

- The health hazards associated with respirable crystalline silica exposure.

- The purpose and description of the medical surveillance program.

- The proper use and limitations of engineering controls and respiratory protection.

- Develop and implement training programs to educate miners on:

-

- Documentation:

-

- Maintain records of all training sessions, including dates and attendees.

-

Exceed MSHA with BreatheSafe

MSHA |

BreatheSafe |

Permissible Exposure Limit |

|

|

Permissible Exposure Limit (PEL): Miners’ exposure to respirable crystalline silica must not exceed 50 micrograms per cubic meter of air (µg/m³), averaged over an 8-hour time-weighted average (TWA). Action Level: If exposure levels reach or exceed 25 µg/m³, averaged over an 8-hour TWA, mine operators are required to implement additional protective measures, including exposure monitoring and medical surveillance. |

|

Monitoring and Reporting |

|

|

Exposure Monitoring: Regular sampling will assess miners’ exposure to respirable crystalline silica. Use sampling devices that meet the characteristics of respirable-particle-size-selective samplers as specified in ISO 7708:1995. Reporting and Recordkeeping: Promptly notify miners of their exposure levels following sampling. Maintain accurate records of all exposure measurements and corrective actions taken. |

|

Engineering Control |

|

|

Implementation: Employ feasible engineering controls to reduce and maintain miners’ exposure to respirable crystalline silica at or below the PEL. Respiratory Protection: When engineering controls cannot maintain exposures at or below the PEL, provide miners with appropriate respiratory protection under ASTM F3387-19 standards. |

|

Training and Education |

|

|

Training Programs: Develop and implement training programs to educate miners on: The health hazards associated with respirable crystalline silica exposure. The purpose and description of the medical surveillance program. The proper use and limitations of engineering controls and respiratory protection. Documentation: Maintain records of all training sessions, including dates and attendees. |

|

What You Need For MSHA Silica Rule

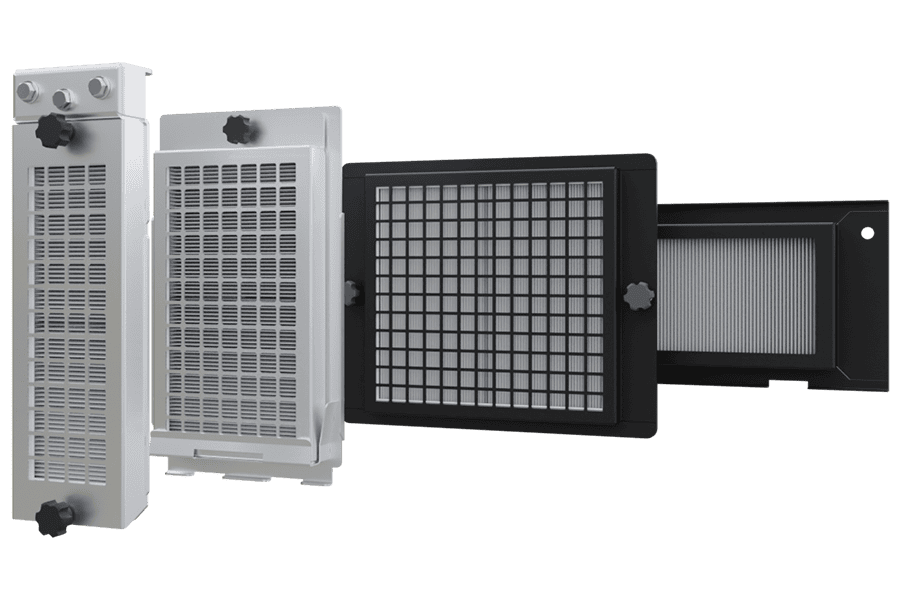

Closed-Circuit HEPA Filtration

High-Efficiency Filters

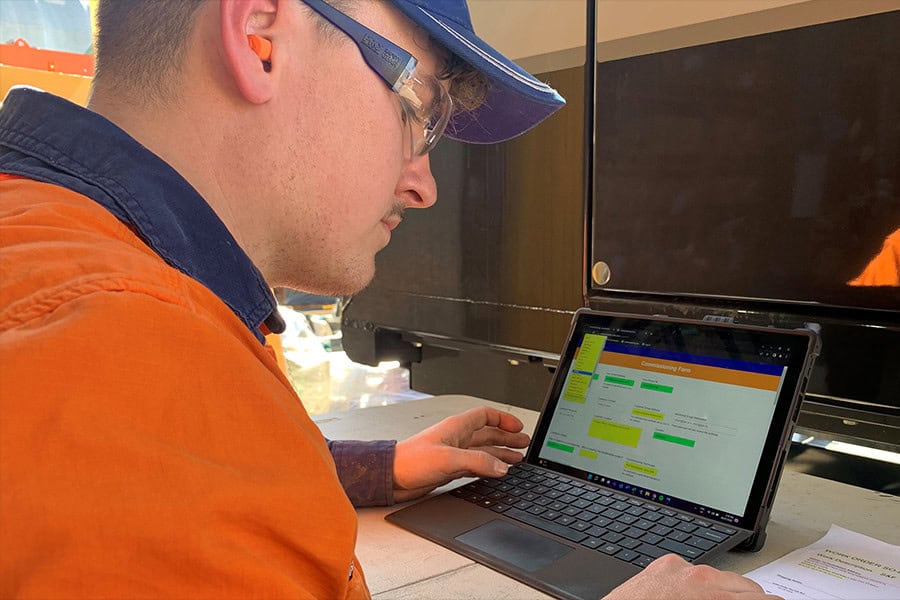

Controller with TWA Feature

System Auditing Registry

Media

Need an MSHA Silica Rule Solution?

Speak with our team to ensure your systems meet and exceed MSHA requirements in any environment.