New MSHA Rule. New Standard. Are You Ready?

The Mine Safety and Health Administration (MSHA) has introduced new silica exposure limits that will change how mines manage air quality.

BreatheSafe helps operators meet these standards with engineered air-filtration and monitoring systems that keep your workforce safe and your operation compliant.

Understanding the New MSHA Silica Rule

The new rule represents one of the most significant regulatory updates in decades. It lowers the permissible exposure limit for respirable crystalline silica and enforces stricter monitoring and reporting requirements.

Compliance timeline:

The rule took effect on 17 June 2024. Enforcement for coal operators begins by the end of October 2025, and for metal and non-metal operators on 18 April 2026.

Permissible Exposure Limit Has Been Tightened

The permissible exposure limit has been reduced to 50 micrograms per cubic meter, with an action level of 25 micrograms. Operators are now required to conduct continuous, full-shift sampling instead of relying on an eight-hour sample.

If exposure levels exceed the new limits, immediate corrective actions must be taken, including engineering or administrative controls, and the results must be reported directly to MSHA.

Engineering Control > PPE

Personal protective equipment is no longer considered a permanent control method. The rule clearly prioritises engineering and administrative controls. Respirators may only be used temporarily until effective engineering solutions are implemented.

This new standard aligns mining regulations more closely with OSHA’s silica requirements and raises the industry’s expectations for air quality management.

Check Your Compliance Readiness

Many current dust control and monitoring systems will not satisfy these updated requirements. A full reassessment of your site’s air quality control systems is now essential.

How BreatheSafe Can Support Your Operation

BreatheSafe delivers comprehensive air quality solutions built specifically for mining environments. Our systems are designed to exceed the MSHA Silica Rule and ISO 23875 standards, providing continuous clean airflow and real-time data that verify compliance every shift.

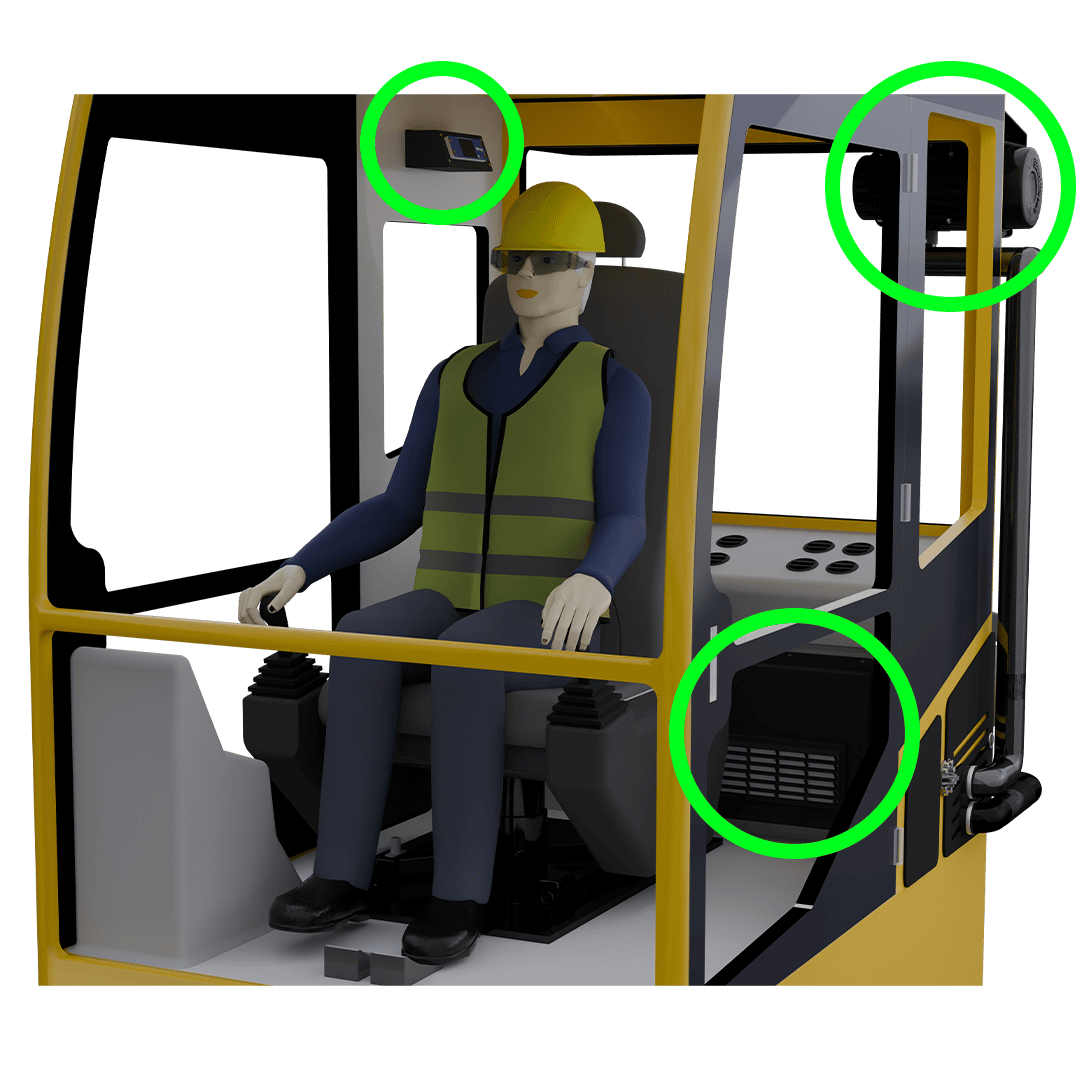

Complete Air Filtration System

BreatheSafe provides fully engineered air filtration systems built for your machine and proven in the harshest mining environments.

Backed by global support, each system delivers optimal airflow, pressurisation, and protection, exceeding MSHA, ISO 23875, and site-specific requirements.

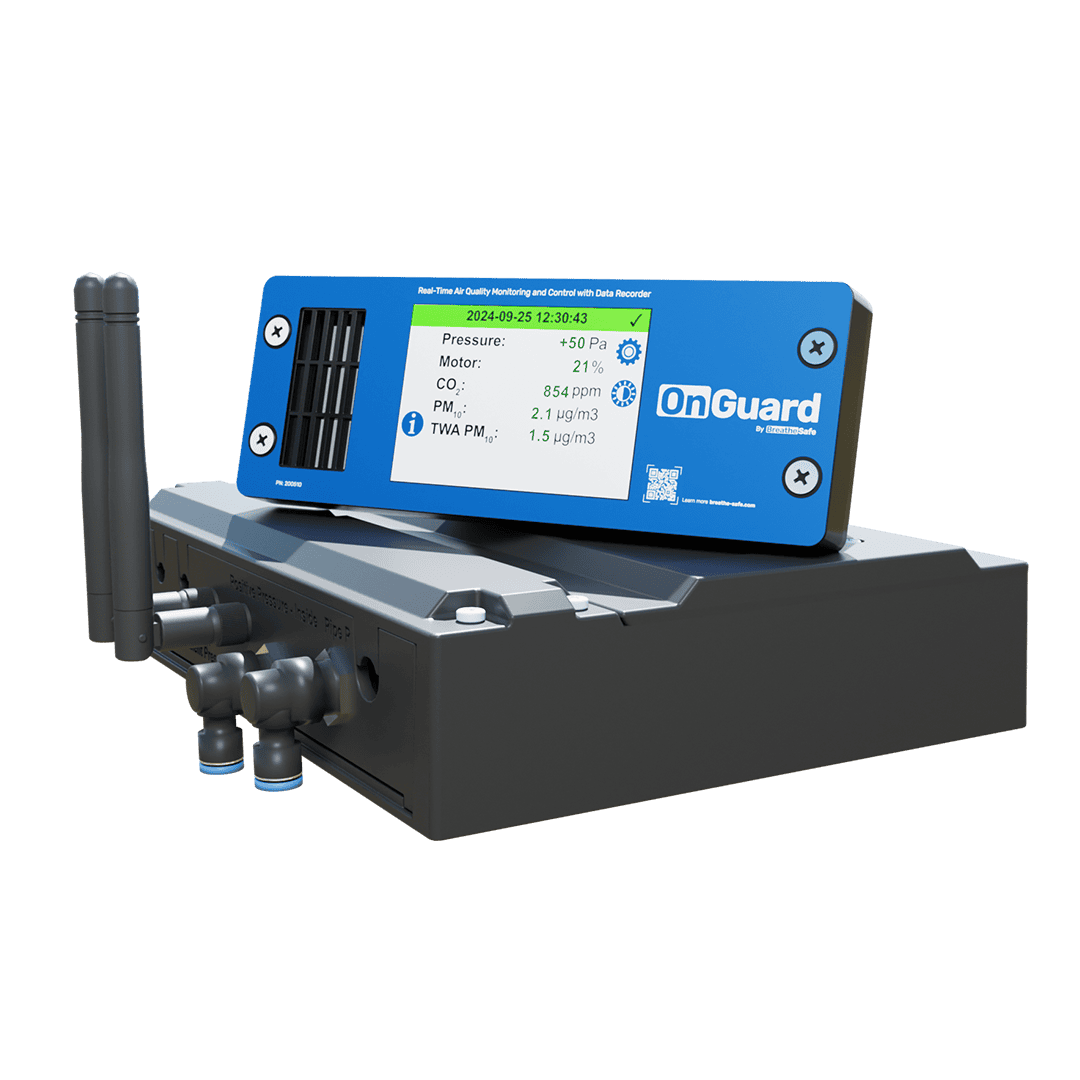

OnGuard™ Air Quality Management

The OnGuard platform provides real-time and remote control of cabin air conditions, including pressure, CO₂ levels, motor load, and particulate concentration.

It delivers both real-time and time-weighted average data to support documentation and compliance with the new MSHA silica rule.

Highest Grade of HEPA Pressuriser

IP66-rated, equipped with a variable-speed brushless DC motor and H14 HEPA filtration to maintain constant positive cabin pressure.

This prevents contaminant ingress and ensures a continuous supply of clean air for operators in dusty environments.

High-Efficiency Air Filters

BreatheSafe systems exceed MSHA and ISO 23875 standards with the highest HEPA-grade filtration.

They protect operators from crystalline silica, diesel particulates and more, delivering the highest filtration performance in the industry.

Why BreatheSafe?

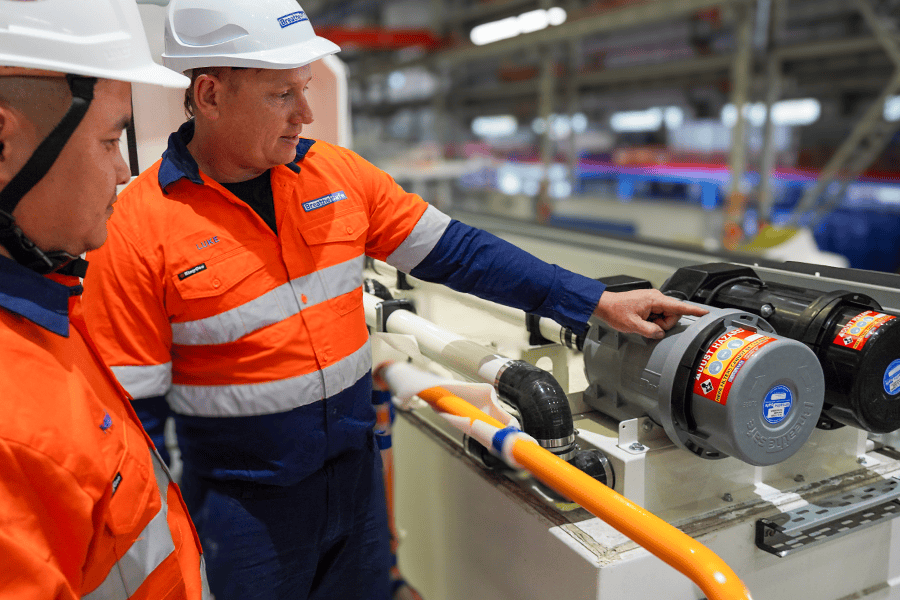

Built with the Industry.

Trusted by Australia’s Leading Mine Sites.

Tier 1 & Tier 2 Operators

Used across WA, QLD, and NSW mining operations

20+ Years Experience

Developed with decades of mobile filtration innovation

OnGuard Technology

Real-time remote access to the air quality of your fleet

Compliance Aligned

Meets Safe Work Australia and MSHA Silica Standards