English TranslationMientras BreatheSafe se prepara para exhibir en Perumin, del 22 al 26 de...

Saving Lives in the Smoke: A New Approach to Firefighter Safety

Saving Lives in the Smoke: A New Approach to Firefighter Safety

Firefighters battle more than flames; smoke filled with toxins poses an invisible, long-term threat to their health. In this interview, BreatheSafe’s General Manager of Engineering and Product, Tommi Perkins, shares how innovations are helping protect those on the frontline.

Q: Tommi, wildfire fighting is one of the most demanding jobs in the world. From BreatheSafe’s perspective, what are the primary health challenges facing these professionals?

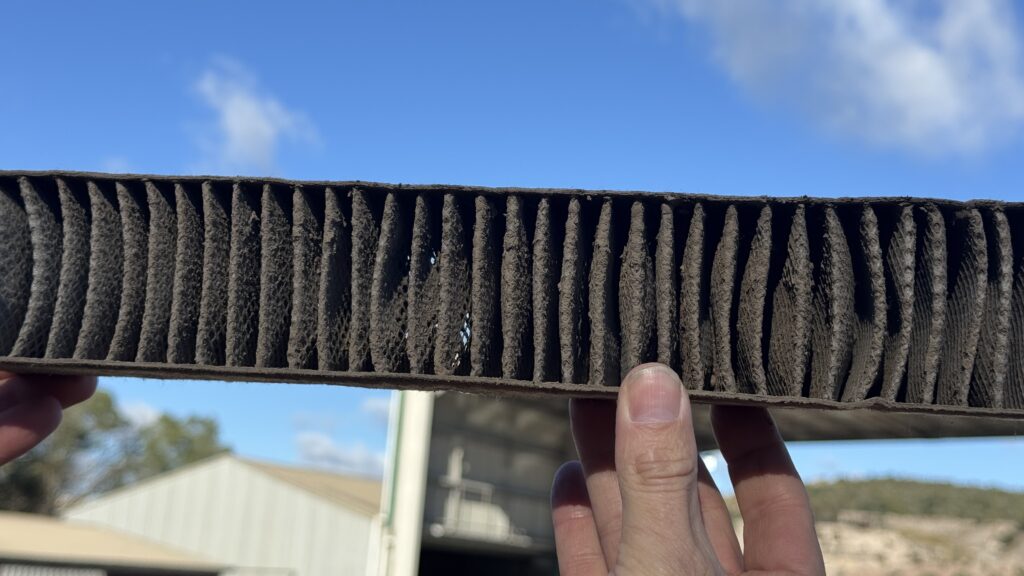

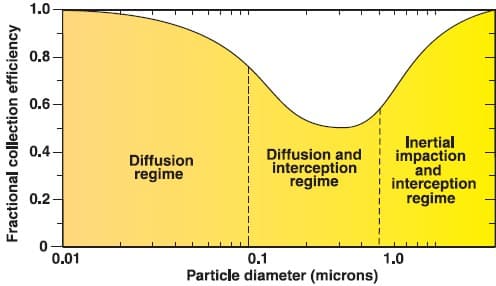

Tommi Perkins: Wildfire firefighters have an incredibly strenuous task, often working up to 24 hours straight in high-temperature and high-smoke conditions. For a long time, smoke from wood fires was presumed relatively safe, but research has proven this is not the case. The smoke contains a dangerous mix of gases and particulates, with studies identifying up to 31 carcinogens.

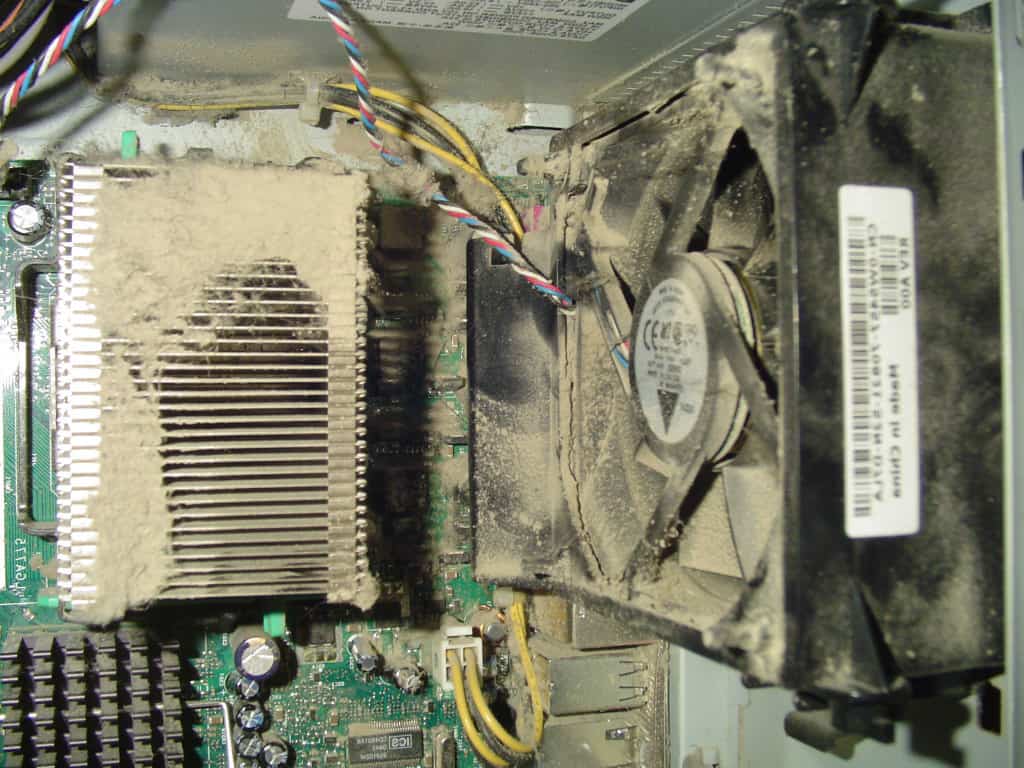

The challenge is that prolonged exposure to these fine particulates and gases, which is an industry given, causes significant and permanent lung damage. This can lead to cancers, COPD, and other serious respiratory illnesses. Many in the industry still believe they can’t burden firefighters with PPE because of the risk of overheating in a high-intensity, remote environment, but modern medical research is now highlighting the massive damage being done to firefighters’ lungs.

While wearing heavy PPE in the field can be impractical, we can still protect firefighters by creating a clean and safe breathing environment inside the enclosures of their vehicles and heavy machinery, where many are either operating or taking a moment’s respite.

Q: So, how does BreatheSafe’s general solution, used in mining and construction, translate to this unique environment?

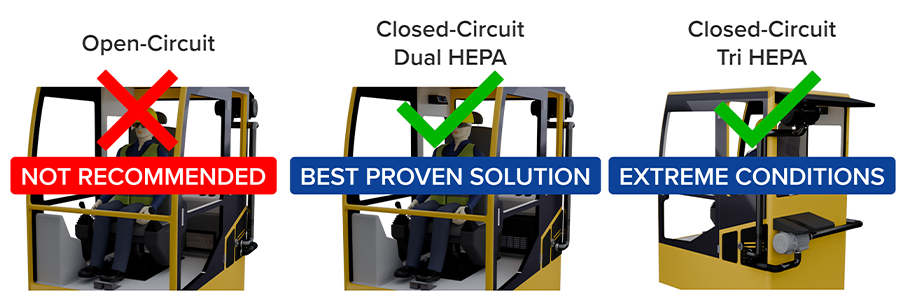

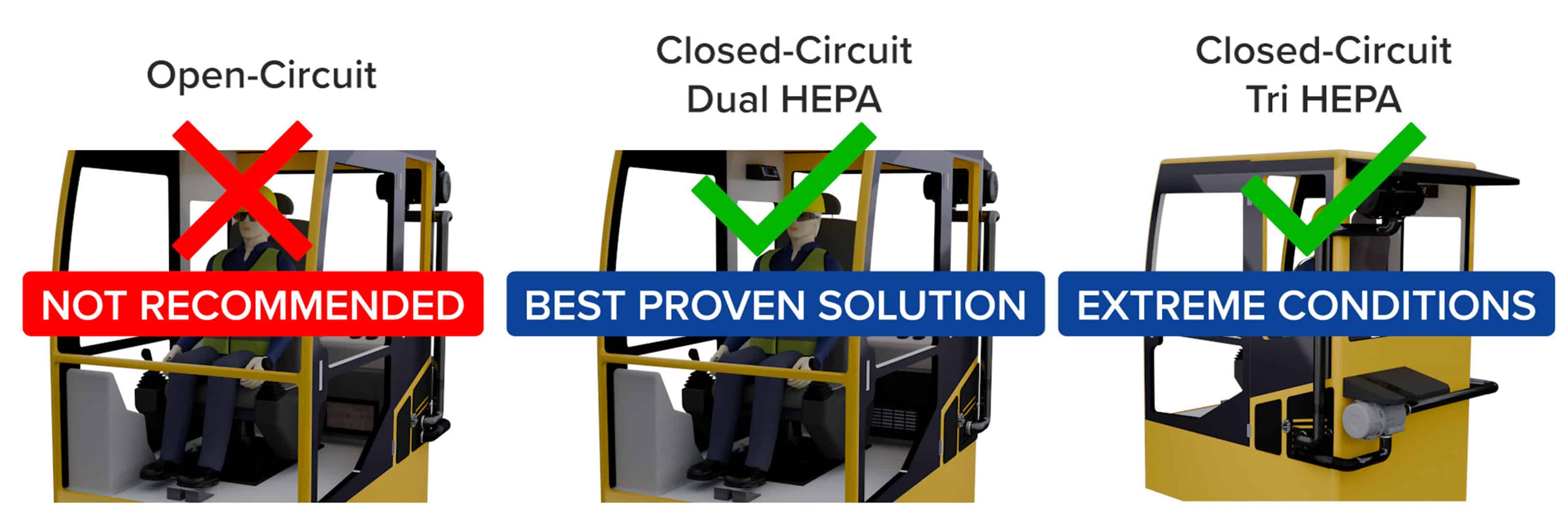

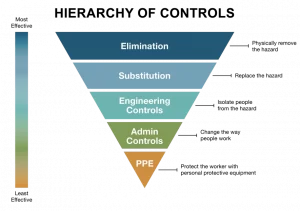

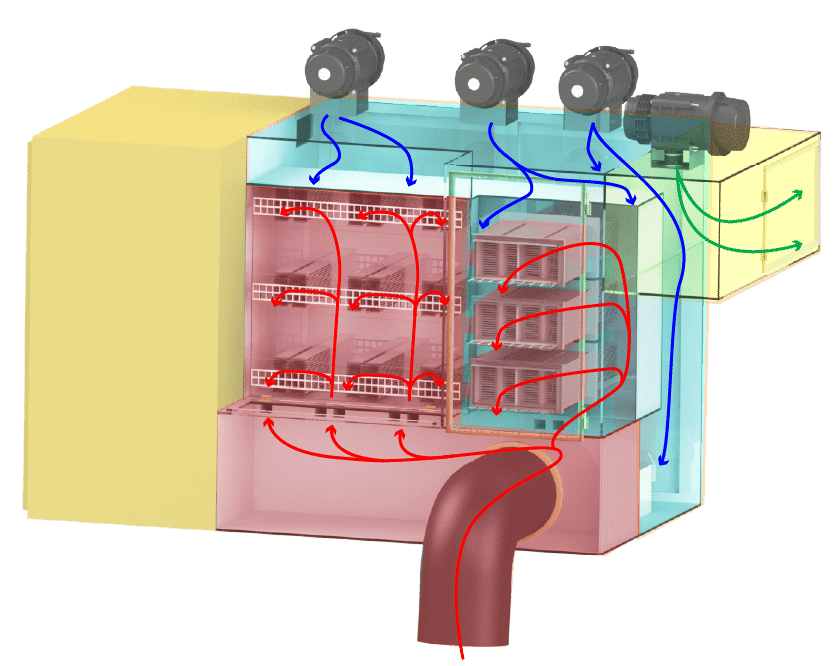

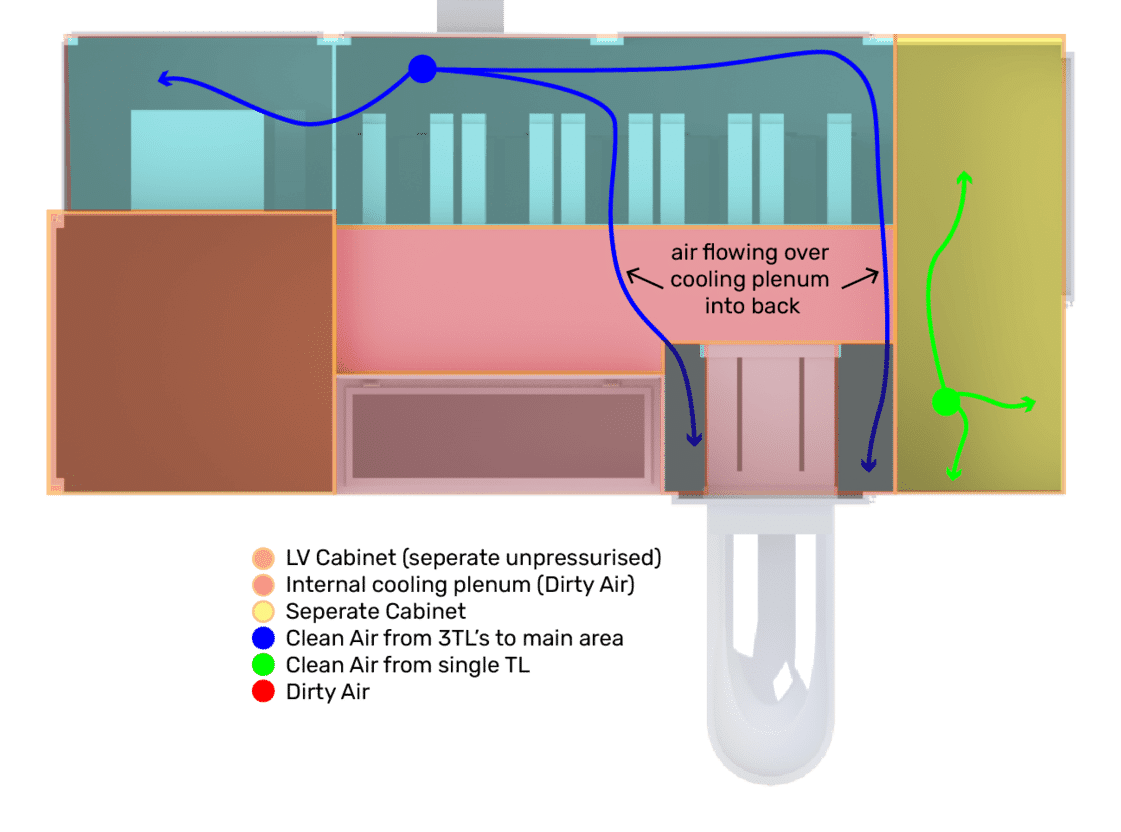

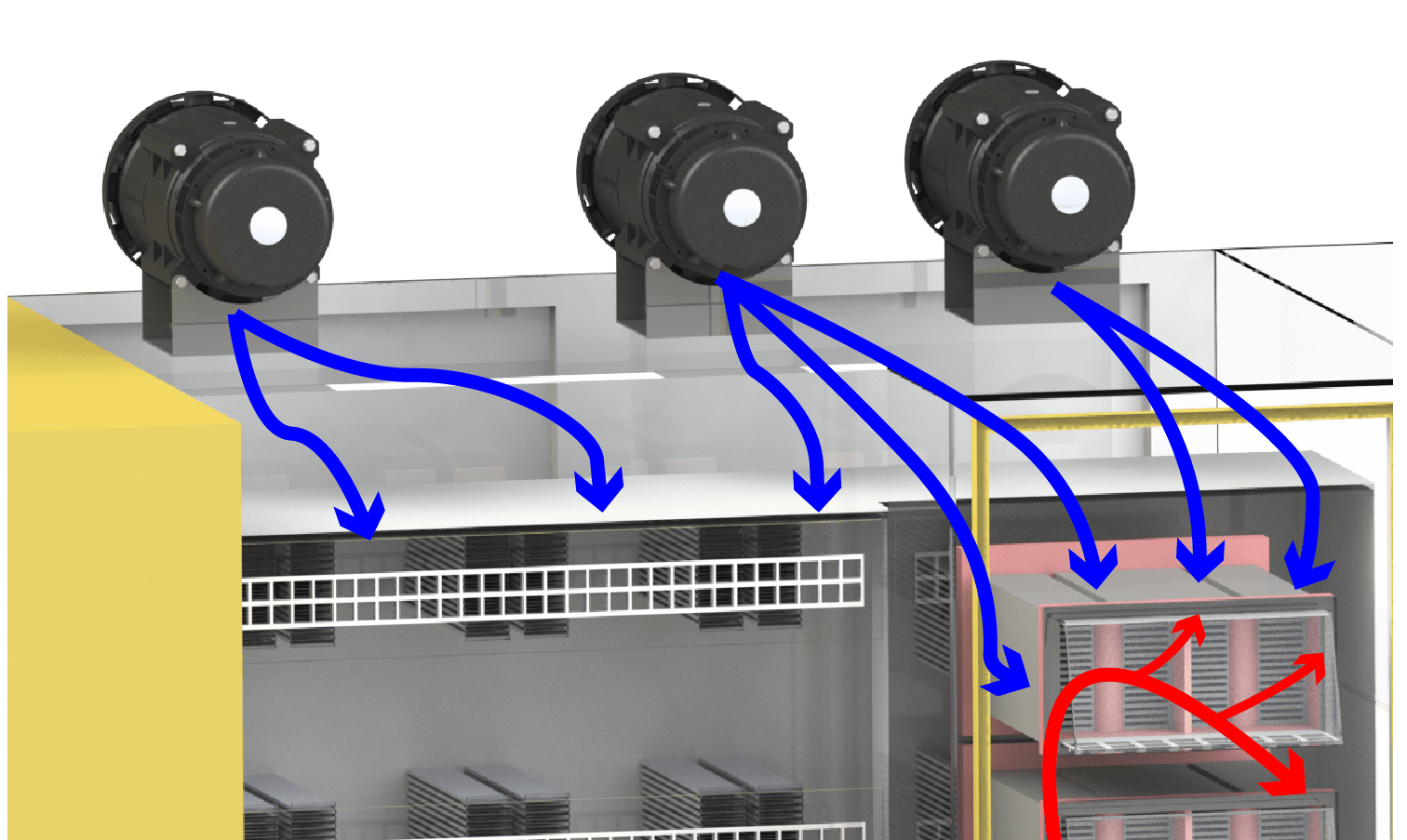

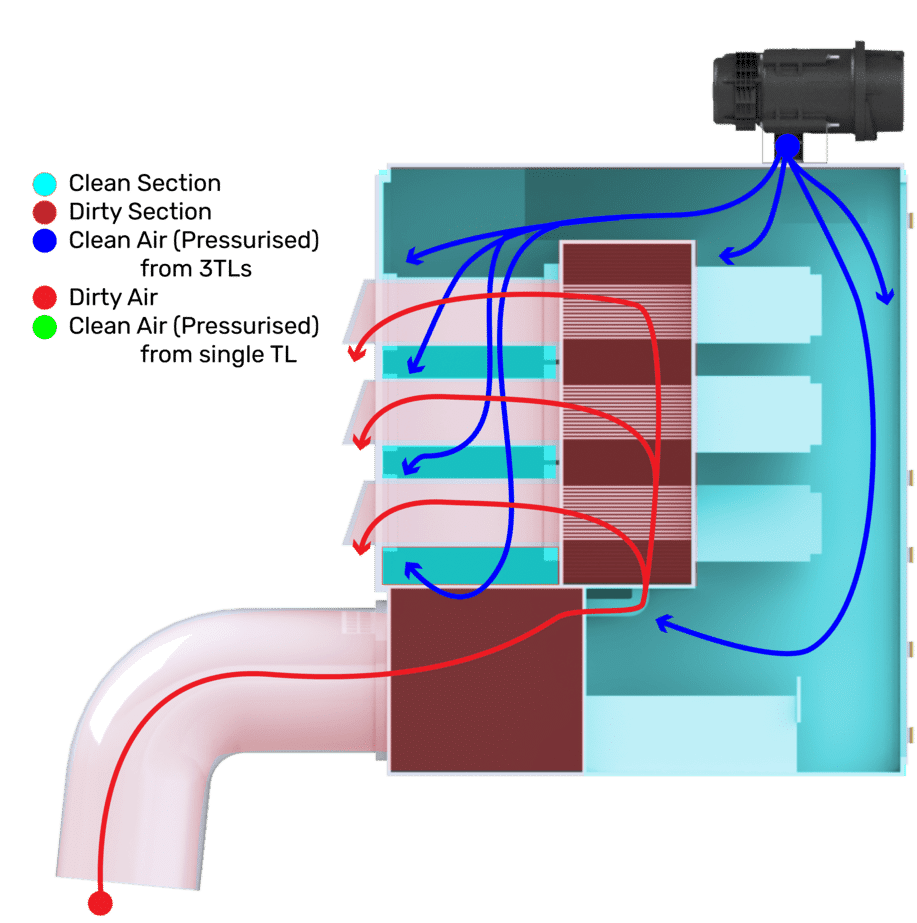

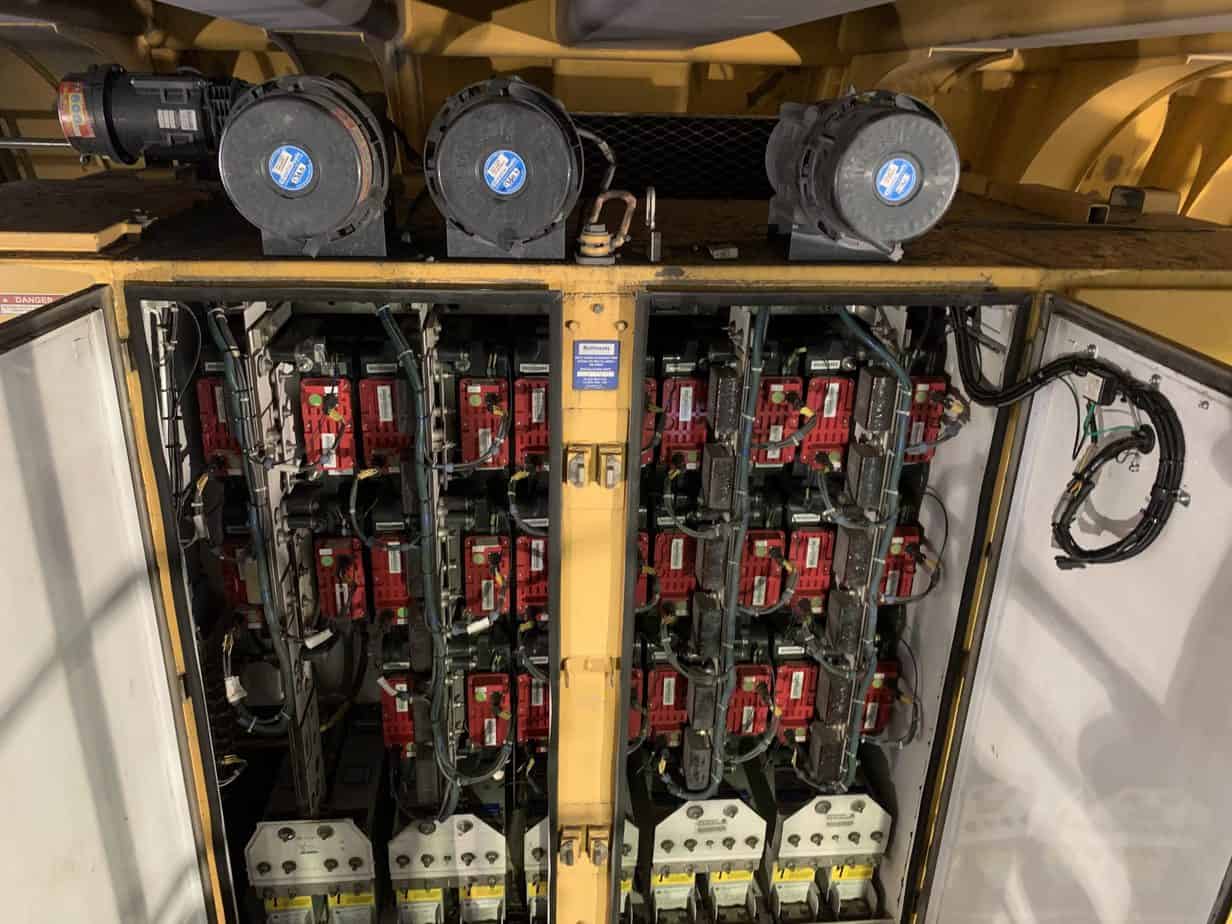

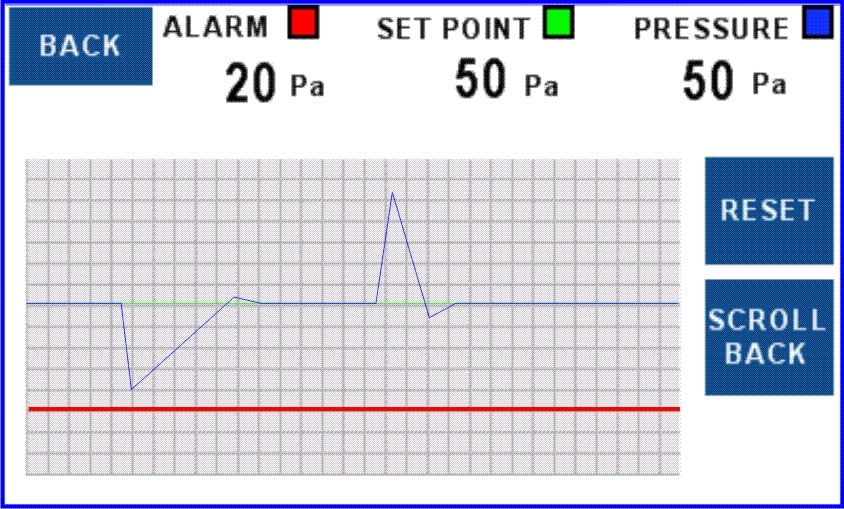

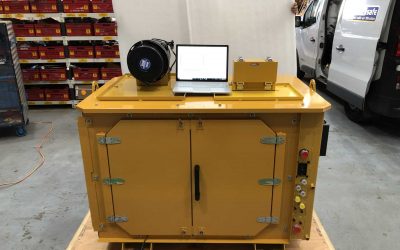

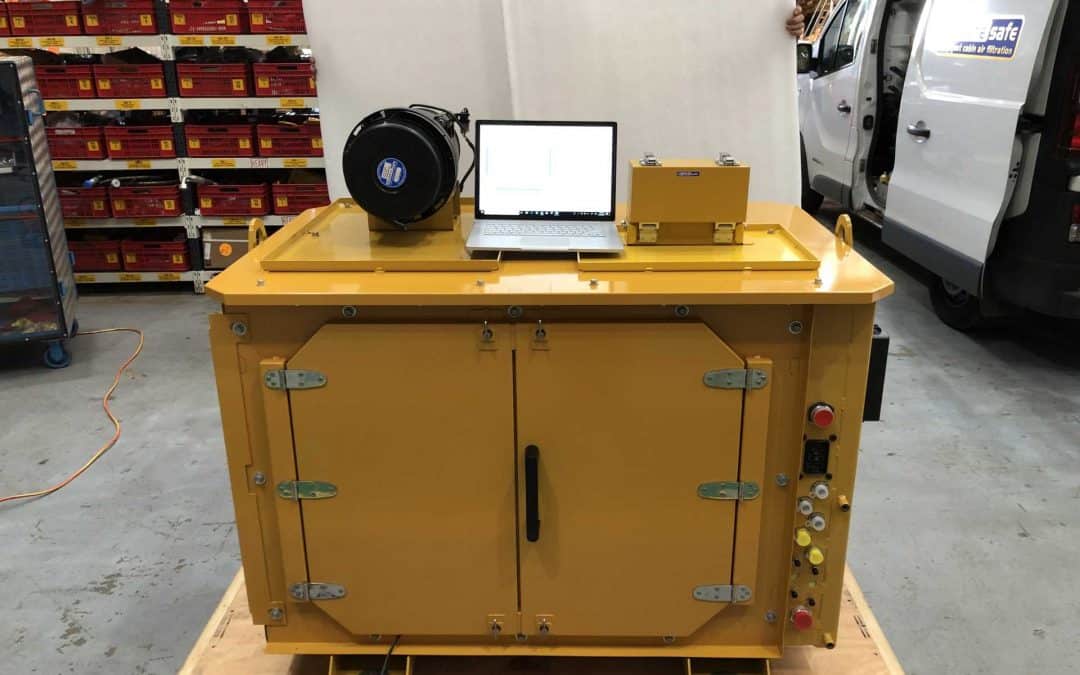

Tommi Perkins: The approach is very similar. The solution is to protect the entire enclosure rather than just the person, and it’s a tried and tested method. We can isolate any enclosure from the outside air, like a dozer cab or a crew transport vehicle, by creating positive pressure inside. By delivering high volumes of purified, clean air into the space, the internal air is constantly pushed out. This ensures that none of the gases, dust, or ash from the outside environment can make its way into the enclosure.

The only way for air to get inside is through our filtration system. This creates a safe environment where firefighters can step in, take off their heavy gear, and cool down, confident that the air they are breathing is purified and safe.

Q: Firefighting poses some very specific risks that mining might not. What modifications or additions have you made to address the reality of flames, heat, and embers?

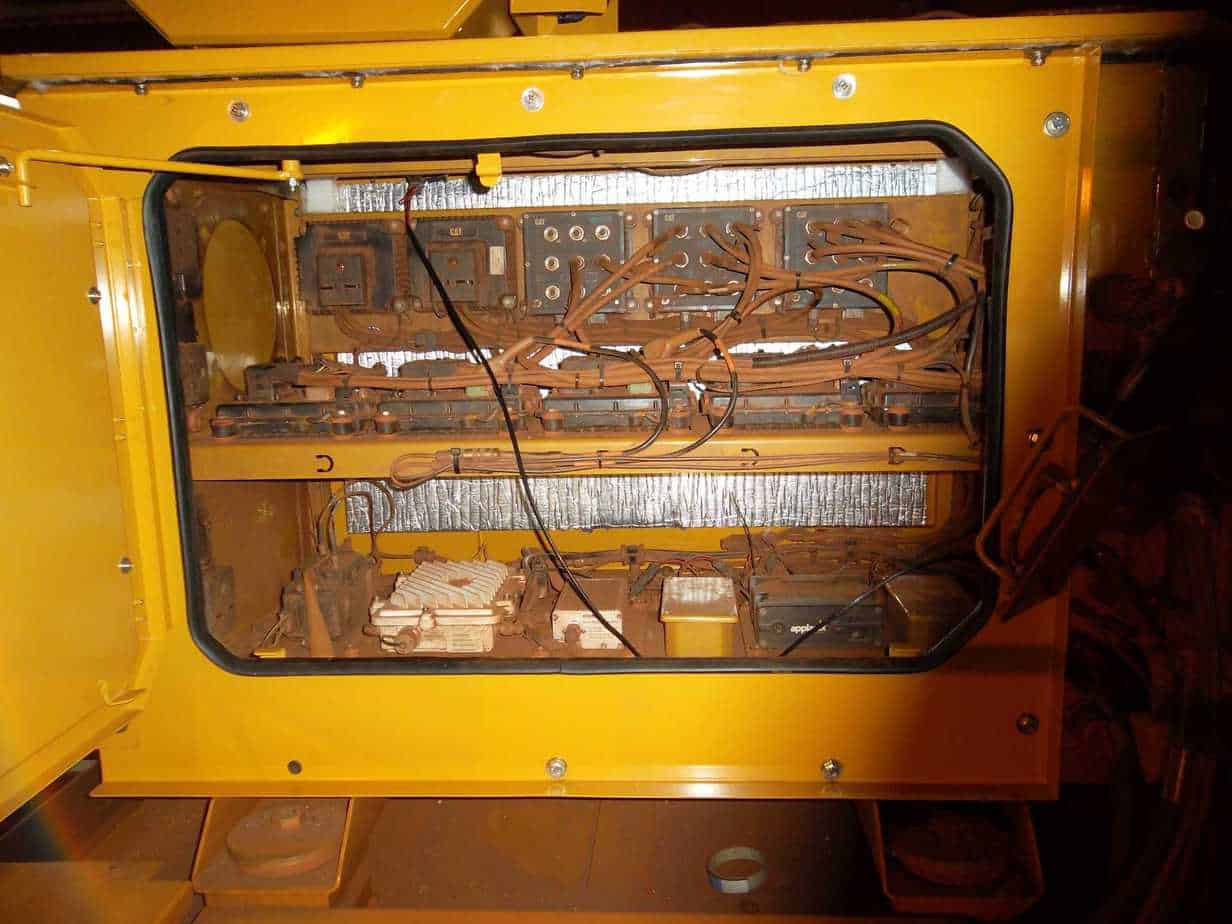

Tommi Perkins: You’re right, the threat of flying embers is a key concern. Our solution for firefighting equipment, such as dozers that are literally pushing burning trees, includes a spark arrestor and a pre-cleaner to extinguish embers and remove heavy ash and soot before it reaches the air filter. We also use heat-resistant and flame-retardant filters to ensure that the system can withstand high-temperature air.

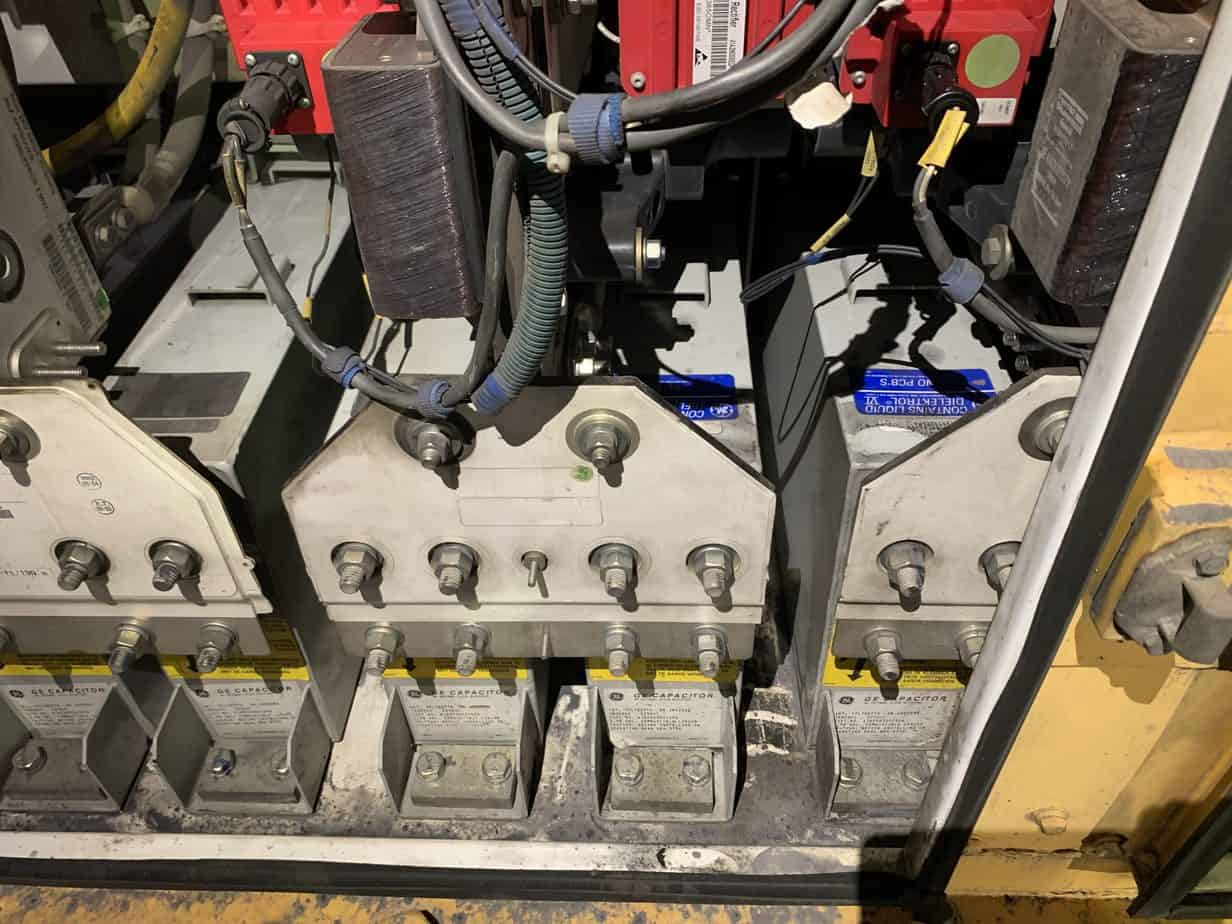

Another critical modification we’ve made addresses the issue of heat. The last thing you want to do is introduce 176°F (80°C) air straight into the cabin onto an already hot and uncomfortable crew. We have designed a system that mixes the incoming air with the machine’s already cooled air from the air conditioning system before it passes through multiple stages of filtration. This ensures the air introduced is safe to breathe and also helps the firefighter cool down, as well as continuously filtering the air inside the cabin. The process of mixing and cooling the incoming air before it is moved into the enclosure is actually part of a patent-pending system.

Q: What about the types of vehicles and machinery used in firefighting? Can you provide solutions for all of them?

Tommi Perkins: Yes, we can. We have designed systems for a wide range of vehicles, from frontline dozers and fire engines with huge cabs to emergency crew transports and even light support vehicles. While a lot of fire equipment has sufficient excess power for our systems, a key challenge is that these vehicles are not built with adequate sealing, unlike modern mining equipment.

The industry is also poorly addressed right now. I’ve seen some existing proposed solutions, which filter the air in the space immediately around them, like a home room purifier, which means they’re only targeting air already inside the cabin and not necessarily in the breathing zone of the crew. There is nothing right now that provides a comprehensive solution. Our unique approach of filtering all incoming air and then mixing it with the air inside the cabin is something no one else has done yet.

Wildfire smoke is a silent threat to firefighters’ health. BreatheSafe’s cabin protection systems provide clean, cooled air and a safe space to recover—so our frontline heroes can keep breathing safely.