Automatic dust data monitoring and alerting removes many opportunities for human error and increases safety and productivity in the workplace

Data Monitoring: The Key to Success in Minimising Exposure to Dust

Data Monitoring: The Key to Success in Minimising Exposure to Dust

August 31, 2021 (Photo updated October 19, 2023)

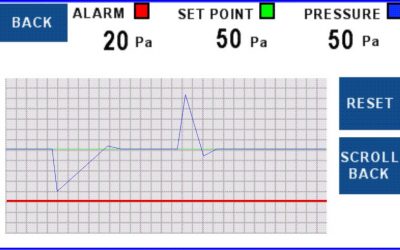

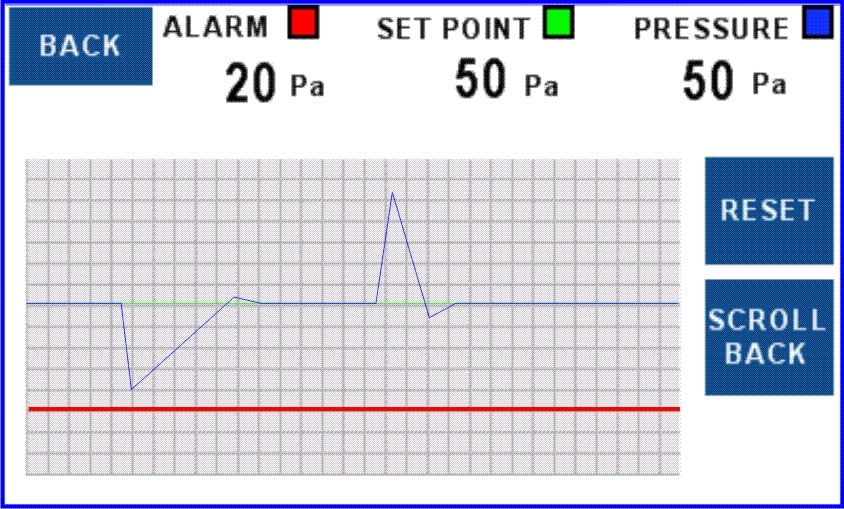

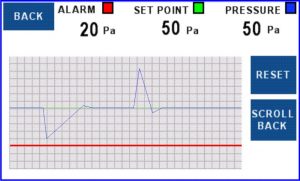

Remote data monitoring is the way forward for site operations—real-time warnings and long-range data to review help set risk management plans to prevent lung disease. Having fully automatic data logging and alerting removes many opportunities for human error and is cost-effective in the long term. Access to this data provides convenient visibility and allows managers to make informed decisions to increase safety and productivity in the workplace.

Monitor System Performance

The greatest asset of a risk management plan is to have actual proof that an installed system is performing as designed; to the required level and outcome.

Long-term data log values assist in evaluating the gains in performance. Data on the filter’s efficiency and potential events leading to exposure risks helps evaluate the installed filtration system. If there are many exposure events or the filter is filling quickly, it allows maintenance extra access to understanding where performance hindering lies. However, if performance is recorded as being successful and efficient, it can justify the costs of the filtration system and allow calculations of value provided.

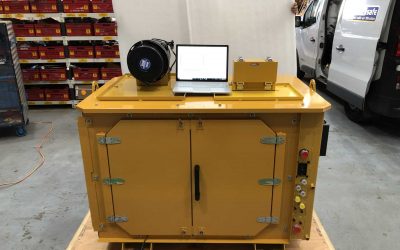

The performance gains are significant when utilising innovative technology such as the extended service cycle of brushless motors and filtering the correct volume of fresh air. BreatheSafe High Pressure Air Filtration systems automatically control these important performance aspects and record data for downloading to ensure optimal performance.

Monitor Operator Training Effectiveness

The most crucial factor is keeping the working environment clean and free from airborne particulate matter, which can only be achieved with operator involvement.

Training must be part of the respirable dust risk management plan to engage operators. Training requires measures that must be encouraged and kept, such as always keeping doors and windows closed. Minimising and controlling all potential events that can introduce contamination inside the cabin with respirable particulate.

By recording the number of events and the reason behind the event, supervisors can identify individuals requiring further training or finding areas of improvement in the training program.

Related Articles

Data Monitoring: The Key to Success in Minimising Exposure to Dust

BHP Autonomous Cabinet Field Trial

BHP Trial In 2018, BHP consulted with BreatheSafe concerning airborne mine dust mitigation...

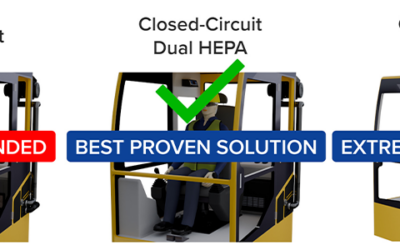

RPME is the best practice to stop respirable dust

RPME is the Best Practice to Stop Respirable DustJune 06, 2021BreatheSafe Air Pressuriser System...